How BioBots' $5K 3D bioprinter could make doctors and medicines more effective

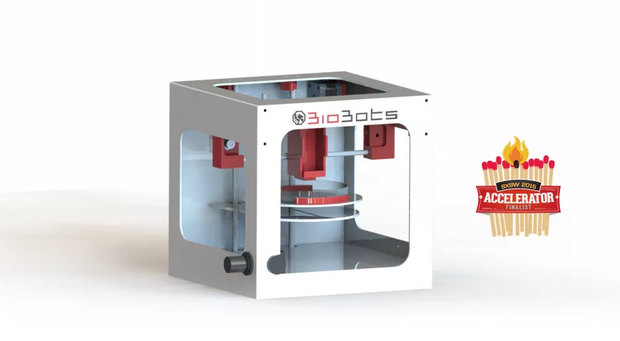

Image: BioBots

While he was in college, Ricardo Solorzano spent more than three years working under scientists to push the frontiers of regenerative medicine. He saw the field quickly moving toward 3D bioprinted organs -- that scientists are getting closer every day to turning what seems like an impossible science fiction experiment into reality.

He started building a next-generation device in his dorm room at the University of Pennsylvania's Engineering School, with the help of Daniel Cabrera, a biology and computer science student, and another student Sohaib Hashmi.

What resulted was the first prototype of BioBots, a high-resolution desktop 3D bioprinter that builds human tissue. After more iterations, the team built out the final version of the desktop 3D bioprinter, and it only costs $5,000.

If you don't know much about bioprinting, that may not seem as unbelievable as it actually is. But that cheap of a bioprinter is unheard of. 3D bioprinting is still in its nascent stages. There are several companies and universities already pushing the boundaries of the technology for their specific research, but for the general public, experimenting with bioprinting seems like a pipe dream.

One example is Dr. Anthony Atala at Wake Forest Institute for Regenerative Medicine, who has printed ears, cartilage, and skin; another is Organovo, a San Francisco-based company that is printing all kinds of human tissue; and a third -- one that we're particularly excited about here at TechRepublic -- is a six-axis robot 3D bioprinter made by Advanced Solutions in Louisville, Kentucky that is workinf toward printing working heart tissue.

"3D bioprinters are a research tool for most. They're tools that can be used to investigate the cell and molecular biology of tissues today and that will be used to manufacture implantable tissues and organs in the future," Cabrera said. "The problem is that most 3D bioprinters are giant over-engineered monsters that need their own separate rooms, an entire team of dedicated technicians, and hundreds of thousands of dollars to be operated effectively - in other words, they're inaccessible to most researchers that are interested in exploring 3D tissues, they've been a huge bottleneck in the growth and development of the field."

Cabrera and his team want to solve that problem. In short, they want to become the PC of bioprinters.

BioBots has a vision of 3D bioprinters that can sit on every lab bench, giving every biomedical researcher the ability to experiment with 3D tissues. The devices are compact (about the size of the average MakerBot desktop printer) and fairly simple to use. The printer prints cells and other biocompatible material such as cartilage.

So how does it work? The cell solution, which contains living, growing cells as well as vasculature, is extruded from the printer similar to how regular desktop 3D printers work. Then, once the cell material has been extruded, UV light hardens it, one layer at a time.

So the BioBot can be used to print living cell tissue to regenerate organs, or supplemental structures for organs and tissue in the body. Cabrera said BioBots also has potential for the pharmaceutical industry.

"By using 3D tissues built out of human cells in conjunction with animal models they will gain a much deeper understanding of which compounds work, saving millions of dollars in the drug development pipeline," he said.

Some early adopters of the printers include Dr. Kara Spiller at Drexel University, and clients in New York, Australia, Indiana, and Maryland. Cabrera said the company is taking orders via the website, and they'll head to SXSW this month to pitch as an accelerator finalist.

"We are using the BioBot printer to build complex tissue-like structures that will allow us to study the processes that occur in tissue development and disease," Spiller said. "We hope that these insights will lead to the development of new drugs or strategies to stimulate tissue regeneration following injury. We may also be able to use tissue engineering techniques to grow new tissues in the lab in order to replace damaged tissues in the body."

Cell material interactions are critical in every tissue type in the body, Spiller added, so there is a lot of potential for the printers. And since they're affordable, she feels comfortable recommending them to other colleagues and researchers.

"They're small enough to be portable, so you can bring them to a colleague's' lab, and to fit easily in a sterile culture hood, making cell culture easier," she said.

With more affordable bioprinters like BioBots, the technology becomes more democratized and research developments can happen faster. Bioprinting is one of the most intriguing areas of the 3D printing industry, and the next decade will be exciting as technologists and physicians team up to figure out how to effectively 3D print working body parts.

In 2015, the Oxford English Dictionary added "bioprinting" as an official word. However small, for those of us who have been watching this industry closely, that's quite an exciting development in itself. Just take a look at their example sentence:

"Welcome to the age of bioprinting, where the machines we've built are building bits and pieces of us."