Why desktop 3D printing still sucks

This article, Why desktop 3D printing still sucks, originally appeared on TechRepublic.com.

Image: Lyndsey Gilpin/TechRepublic

This time last year, the hype for desktop 3D printing was at an all-time high.

Though the technology is more than 30 years old, there was a surge in growth in 2014. Crowdfunding jump started startups in the space, companies like MakerBot and 3D Systems unveiled more affordable models at CES and other big tech conferences, and the maker community really latched on to 3D printing's democratizing, open-source mission.

I've been writing about 3D printing since early 2014. I've seen virtually every type of 3D printing object that's out there. I played around with the MakerBot Mini when TechRepublic ordered it (actually, we had to order three before one worked) last year. I've seen the Cubify, RepRap, and Formlabs in action, and I've spoken to many experts in the industry about the evolution of this technology. And finally, I recently assembled, tested, and reviewed the Ultimaker desktop printer at the office, and wrote a review of it.

The conclusion I came to? Consumer 3D printing, no matter the brand of hardware, needs a whole lot of work. The hype has calmed down and we're starting to be more realistic about the technology -- Gartner's 2014 hype cycle report tells us consumer 3D printing is now in the "trough of disillusionment," which it defines as when "interest wanes as experiments and implementations fail to deliver. Producers of the technology shake out or fail. Investments continue only if the surviving providers improve their products to the satisfaction of early adopters." Sounds about right.

Desktop 3D printing has a lot of potential, so let's talk about what the problem is, and how to improve it.

1. It's still a dumb technology

The way it's advertised, you'd think you could set up your 3D printer, hit print, leave for the day, and return home later to an item made out of thin air that you can use immediately. It's like Christmas morning, right?

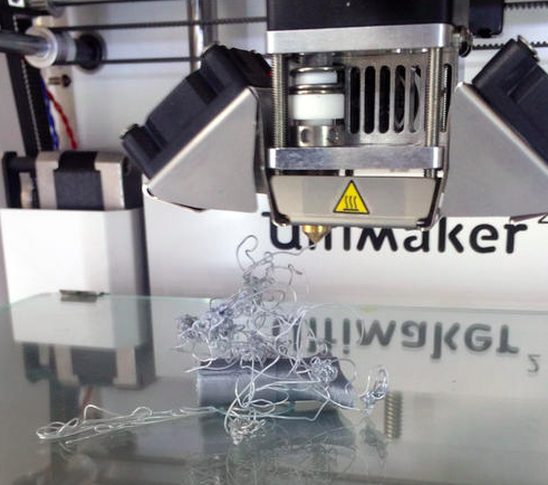

Unfortunately, that's not exactly the case. You may come back to a tangled mess of plastic, or an extruder printing with no plastic coming out at all. It might be jammed, paused, beeping, or flashing lights. It may have never started at all. This is mainly because there is no sensor on the extruder head of desktop printers, so it doesn't know when it's off track or if it knocks the object over -- it just keeps printing away. You end up with wasted filament, and have to start the print over, which usually takes at least an hour. It's also not exactly clear what went wrong with the print, and the software doesn't tell you. So you could start the print again, and have the same issue. A sensor that automatically stopped the print when something like this happened would probably fix the problem, and it will probably be in every extruder in a few years.

What's more is that 3D printers are bulky and noisy, and the software that runs them is often unintuitive. Most brands of desktop 3D printers come with their own software system to design and download prints, and an open source platform with a library of prints. Though they're usually compatible with platforms like Thingiverse (so you can print most things without knowing CAD software), sometimes the designs don't translate correctly between programs, and the individual designs offered are

2. The novelty wears off fast

My jaw dropped when I started 3D printing my iPhone 5S case, and it stayed like that for pretty much the two hours it took to finish the print. I barely took my eyes off of it, feeling quite attached to the process. There's something empowering about making an item like that yourself, instead of buying it from Amazon or Target. Even if the technology isn't perfect, it's still pretty amazing that we can download a design, hit a few buttons, and magically print something.

The promise of 3D printing is that it will make manufacturing more efficient, products more customizable and replaceable, and as users, we'll be more creative and independent. But, that's not quite true. In fact, after a few frustrating runs that ended in globs of plastic instead of actual objects, we hit a wall and couldn't think of anything worth trying to print.

Excitement gives way to the realization that desktop printers are the slow to produce, constantly make mistakes, and overall, are a bit of a time suck. The only material option is cheap plastic, color options are limited, and not enough companies have made 3D printing designs available to the public yet. It's all still talk, unless you just want to print smartphone cases, mini robots, and sad Keanu figurines -- and hey, I'm not judging.

3. The workflow is too difficult

This is a combination of the two previous points. Because the software and hardware aren't mature, it makes the process of 3D printing a headache. Though most printers come mostly assembled out of the box, they still require a lot of set up and often a Wi-Fi connection or USB transfer to download prints off of open source platforms.

The actual printing process takes at least an hour, and the only items desktop printers can make are quite small. It's loud, and some of them have a strong smell, much like a burning hot glue gun, which doesn't exactly seem safe to inhale. The clean up, which involves unloading the filament, cleaning the build plate, and picking off the extra material that was printed, is a hassle, and what's left from the calibrations, tests, and mistakes is a mess of wasted plastic.

4. The market is premature

With any new technology, the hype is always greater than it needs to be. This was especially the case with 3D printing, as most people focused more on the consumer side rather than what really has potential in the next few years: disrupting businesses in almost every industry. Workplaces can afford better printers, and can use them to make tools and products more efficiently. Medical professionals can print customizable tools. Manufacturers can print spare parts, like how Boeing prints small parts for its jets.

Even still, we still need a wider variety of materials, more affordable options, more reliable technology, and better software.

Of course, we're all just starting to wrap our heads around the potential for 3D printing. It will just take time for the market and the technology to mature, and the world to catch up with our ideas.

What have your experiences with desktop 3D printing been like? Tell us in the comments.