What cars are made in Kentucky? See which Ford, General Motors and Toyotas are built here

Was your car made in Kentucky? Possibly.

Situated in the geographic center of "Auto Alley," a cluster of the motor-vehicle industry that spans across North America, the Commonwealth is at the forefront of vehicle production.

According to information from the Automotive News Data Center, Kentucky is the number one producer of light vehicles per capita and a top three producer of passenger vehicles overall.

"Kentucky has been a national leader in the automotive industry for decades," said Brandon Mattingly, director of marketing and public affairs at the Kentucky Cabinet for Economic Development. "The automotive industry is one of the most vital industries in the Commonwealth with more than 550 auto-related facilities currently operating in two-thirds of Kentucky’s 120 counties and employing over 103,000 people."

Kentucky is home to four major automakers and will be the future home of several electric vehicle, or EV, related production plants.

"The presence of these companies represents thousands of quality jobs for Kentucky residents as employment has increased significantly across each of these operations throughout the years," Mattingly told the Courier Journal.

You may like: Coming to a dealership soon: Ford ships 2023 F-Series Super Duty trucks built in Kentucky

Here's what we know about the automakers in Kentucky:

Ford Kentucky Truck Plant

3001 Chamberlain Lane, Louisville; Employees: 8,920

Vehicles produced: Ford F-Series Super Duty trucks (F-250 to F-450), Ford Expedition, and Lincoln Navigator

The 500-acre Kentucky Truck Plant opened in Louisville in 1969. This plant has been foundational for Ford Motor Co., producing nearly all Super Duty truck models, including the new 2023 F-Series Super Duty. Since 1999, the Super Duty series has been its own line of Ford trucks.

"This has been kind of a year-and-a-half long party for Ford and Kentucky," Ford CEO Jim Farley said at an event on Wednesday. "We launched that battery plants, we refreshed the Louisville Assembly Plant and now we're launching Super Duty."

The truck plant in Louisville has assembled 13.3 million trucks since 1969, enough trucks to wrap around the globe twice, Farley said. These trucks are the vehicles with the highest profit margin for a 120-year-old company working to slash billions of dollars in recall and warranty costs that have bruised the financials, USA Today reported. Ford Motor Co. builds 100% of all its pickup trucks in America, with the majority being produced in the metro.

You may like: Ford announces 2024 Ford Ranger at Churchill Downs on Kentucky Derby Day

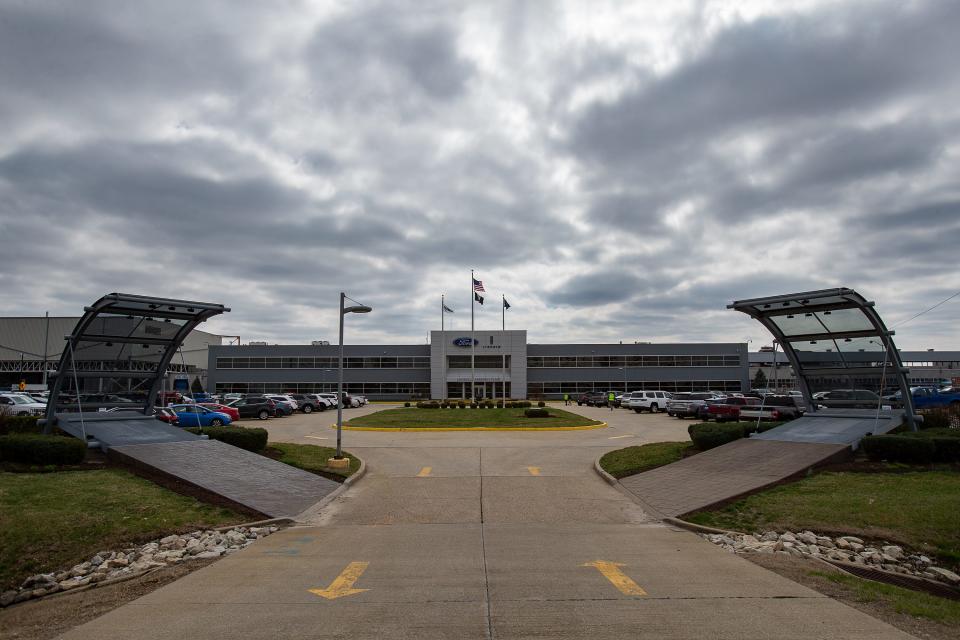

Ford Louisville Assembly Plant

2000 Fern Valley Road, Louisville; Employees: 4,100

Vehicles produced: Ford Escape and Lincoln Corsair

The 180-acre production facility began producing Ford vehicles in 1955. In 1987, Ford beefed up production and added a $260 million investment to produce the Ford Bronco II, which was discontinued in 1990. The Louisville Assembly Plant would go on to see major success in the early 1990s, producing the Ford Explorer. This plant saw a yearlong, full facility makeover in 2010, reopening for production of the Ford Escape in 2011. This past February, the plant experienced a weekslong production shutdown to fix vehicle software for the 2023 Escape models.

What the Louisville Assembly Plant will build in the future is uncertain. Recently, Farley said he wants Ford to move in a direction focused on "passion brands" and not just commodity vehicles like the Ford Escape or Ford Edge.

You may like: Louisville Ford worker wins case alleging union dues wrongly taken

"The Escape and Corsair are very important for the company, but we want to lean into the heritage of Mustang and Bronco and the other iconic vehicles and build new ones like Maverick," Farley said.

General Motors Bowling Green Assembly Plant

600 Corvette Drive, Bowling Green; Employees: 1,368

Vehicles produced: The eighth generation, abbreviated as 'C8' by GM and Corvette enthusiasts Chevrolet Corvette Stingray, the Chevrolet Corvette Z06 and later this year, Chevrolet will begin producing the Corvette E-Ray, the first electrified, V-8 engine, all-wheel drive Corvette.

This plant is the only plant in the world to build the Chevrolet Corvette. Since opening in 1981, the 1.7 million square foot plant has produced more than one million Corvettes. The plant is one of the largest employers in Bowling Green. Over the years, this plant has received more than $770 million in investments. The C8 was the first mid-engine Corvette produced, all prior generations were front engines. Since 2019, the Bowling Green Assembly Plant has donated more than $300,000 to nonprofits in the Bowling Green area.

About a quarter of a mile down the road from the manufacturing plant is the National Corvette Museum. This attraction draws in hundreds of thousands of visitors annually. The production facility offers a one-mile walking tour where guests can see behind the scenes how the Corvette is made.

You may like: Bullitt County welcomes $10M investment for electric vehicle manufacturing, 200+ jobs

Toyota Motor Manufacturing, Kentucky

1001 Cherry Blossom Way, Georgetown; Employees: 9,500

Vehicles produced: Toyota Camry, Toyota Camry Hybrid, Toyota RAV4 Hybrid, Lexus ES 350 and this plant also produces vehicle parts including four-cylinder and V-6 engines, axels, steering components, and more

This production facility is the largest vehicle manufacturing plant globally for Toyota. This facility just north of Lexington, produces more than half a million vehicles annually.

"The plant also plays a critical role in Toyota's global electrification strategy, with an aggressive goal to offer electric or hybrid versions of every vehicle model by 2025," the Courier Journal previously reported.

You may like: Why does Louisville have so many car washes? And why are more coming?

Since the plant opened in 1986, Toyota has produced more than 13 million vehicles in Kentucky. Over the past 37 years, the more than 1,300-acre plant has contributed more than $152 million to nonprofits and educational initiatives. Visitors can take a tour of the plant daily Monday-Friday.

Other vehicle production in Kentucky

While Kentucky is home to four major vehicle manufacturers, the state also supports more than 550 automotive-related facilities statewide. Recently, the growth of electric vehicle related projects across the Commonwealth has expanded, including the two largest economic development projects announced in Kentucky history. Since June 2020, the Commonwealth has seen more than $9.2 billion in EV-related investments and the creation of more than 8,500 full-time jobs.

"Kentucky is primed to lead the charge for the future of the automotive industry," Mattingly said.

In April 2022, Envision AESC, a company that produces EV batteries announced, it would invest $2 billion to build a new plant in Bowling Green that will bring 2,000 skilled jobs to the region. "Our willingness to act now to establish the industry of tomorrow is driving Kentucky forward," Gov. Andy Beshear said of the announcement.

You may like: Buttigieg visits Ford battery park, praises Kentucky for creating 'workforce of the future'

In December, Ford in partnership with SK On broke ground at the electric vehicle battery park in Glendale, Kentucky. The battery park is expected to create 5,000 new jobs in the Commonwealth. The BlueOval SK Battery Park, at 1,500 acres, will be the largest in the world and will start production in 2025. The twin battery plants will produce batteries to power electric vehicles such as Ford’s electric Mustang, F-150 Lightning and Transit.

"This is the site where Kentucky's skilled workforce will produce millions of EV batteries to power the next generations of Ford and Lincoln vehicles," Beshear said in December.

In Hopkinsville, Ascend Elements, a sustainable battery production plant, was awarded two federal grants in October totaling $500 million. The company works to manufacture and process materials to convert them to use in lithium-ion batteries for electric vehicles.

In a release, U.S. Sen. Mitch McConnell said the grants "will help the Commonwealth secure its place as a manufacturing powerhouse."

"This project — which will allow us to source important battery components domestically instead of from rival countries like China — only adds to the significance of this grant for our country," McConnell said.

Rivian, an electric vehicle manufacturer that builds sport utility vehicles and trucks, has a parts operation plant located in Shepherdsville. The automotive company, founded in 2009, already makes vehicle parts inside a 326,000-square-foot facility in Bullitt County. Recently, Rivian announced a $10 million investment in the plant to allow the company to update the facility to include a remanufacturing facility where employees will reconstruct vehicle parts such as electrical hardware, drive units and battery systems.

"Our state’s automotive sector creates opportunities statewide and is central to the strength of our economy," said Mattingly.

Contact reporter Olivia Evans at oevans@courier-journal.com or on Twitter at @oliviamevans_

This article originally appeared on Louisville Courier Journal: Which Ford, Toyota and General Motor cars are made in Kentucky?