This Company Built a Gigantic Centrifuge to Fling Rockets Into Space

A tight-lipped startup called SpinLaunch is ready to start suborbital test flights of its rockets using a gigantic centrifuge. Trials could begin this year.

While the idea seems farfetched, SpinLaunch has managed to secure a contract with the U.S. Department of Defense.

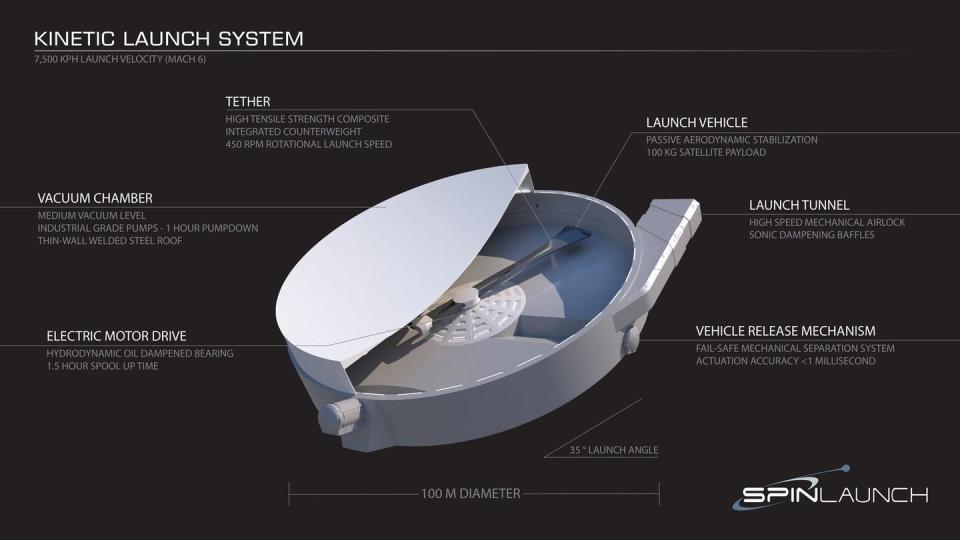

SpinLaunch has built the massive centrifuges to spin rockets at high speed inside a vacuum with minimal friction, hoping to launch rockets at 3,000 miles per hour.

In some biology classes, teachers will place vials of spit into a funny looking contraption and let it spin around the samples until the stringy DNA separates from the rest of the saliva. It's a pretty rudimentary experiment, but it quickly gets to the heart of not only your own genetic material, but also how centrifugal force works: Spinning really fast in a circle creates a force strong enough to push a moving object out and away from the center of its path.

But what happens when that moving object is a rocket that weighs thousands of pounds? We might find out as soon as this year, when a cryptic startup called SpinLaunch starts suborbital test flights of a rocket that is launched using an enormous centrifuge.

Here's the gist: A centrifuge the size of a football field will spin a rocket around in circles for about an hour until its speed eventually exceeds 5,000 miles per hour. At that point, the rocket and its payload will feel forces 10,000 times stronger than gravity. When the centrifuge finally releases the rocket at launch speed, it should, practically speaking, fly through the stratosphere until it fires its engines at the periphery of our atmosphere.

The concept sounds ludicrous, but stakeholders like the U.S. government have taken a liking to it. In June, SpinLaunch signed a responsive launch prototype contract with the Department of Defense to build out its kinetic energy-based launch system that will provide a lower-cost option for the ever-growing satellite industry.

SpinLaunch hopes its new system will replace rocket boosters, which currently augment a rocket's own thrust power to escape the gravitational pull of Earth, and happen to be one of the most expensive components of a rocket launch. Even reusable boosters, like the ones powering the SpaceX Falcon 9, still require costly fuel and ongoing maintenance.

Building the Giant Centrifuge

Beyond the foreign concept of flinging rockets into space by spinning them around in circles until they're going really fast, the hardest-to-swallow pill of the entire project is the sheer size of the centrifuge required to pull it all off. Thing is, you can't just ask contractors to build a giant vacuum chamber for your larger-than-life centrifuge. When the engineers at SpinLaunch did that, they faced a lonely bidder with an estimated price of $20 million—so they built one themselves.

It took the team eight months, a few vacuum pumps on eBay, and $500,000 worth of steel to build the world's sixth-largest vacuum chamber by diameter. This first centrifuge model, while 40 feet across, was still too small to slingshot a rocket into space. Still, it established the underlying design for the final product, which would just have to be bigger.

The prototype also established some of the mechanisms the final centrifuge would need to work. A long arm called a tether, for instance, connects a bearing to a motor, while the payload attaches to the end of the tether. To keep everything in one piece, despite the strain of being tossed in circles at a more-than-dizzying pace, the tether is built from materials with strong structural integrity, like Kevlar and carbon fiber.

In the end, the final centrifuge actually broke the world record for the world's fastest rotational system—not exactly the kind of thing you'd want to replace with an amusement park Tilt-A-Whirl, thanks to its breakneck acceleration.

Since then, the team has tested a bunch of space equipment in the centrifuge: solar cells, radio systems, telescope lenses, GPS, batteries, computers, even an iPhone. All of these could withstand the force of the centrifuge.

Slingshotting Rockets

Most of the launch work is done by the centrifuge, SpinLaunch says, therefore, rockets don't have to be built with extreme efficiency in mind under this framework. Today's rockets can only handle payloads that take up a relatively small fraction of its overall mass, as most of that weight has to be designated for rocket fuel. The 25-foot-long SpinLaunch rocket, by comparison, will be stocky and able to hold payloads up to 200 pounds. Less rocket fuel is required for launch-via-centrifuge.

As the rocket spins in the centrifuge, a port will open for a fraction of a second to let the rocket shoot out. Per company patents, a counterbalance that spins in the opposite direction will also be released to prevent the tether from becoming unbalanced. After coasting for about a minute, the rocket will ignite its engines at approximately 200,000 feet in altitude.

At that point, little atmospheric pressure will be left to challenge the rocket's ascent, so the rocket should only require about a minute's worth of fuel to reach orbital speeds of about 17,500 miles per hour. Finally, a last 10-second burn will push the rocket into orbit.

If all goes to plan, SpinLaunch says it can reduce the cost of sending satellites into orbit by a factor of nearly 20. And to boot, the company believes it will eventually be able to launch up to five rockets per day, which companies like SpaceX can't even do in a month yet.

So ... Does This Thing Work?

For all of the number crunching, physics considerations, and months-long construction projects to build massive, spinning chambers of doom, one lingering question remains: Will it even work?

"It's an exotic technology, and the first time you hear about it you think there's no way that could possibly work," Juan Alonso, an aerospace engineer at Stanford who did due diligence for one of SpinLaunch’s investors, told Wired. But he checked SpinLaunch engineers' calculations and gave the investor a green light. The company has received $80 million of investment from companies like Airbus Ventures, Kleiner Perkins, and GV (formerly Google Ventures).

While the investment world looks gung-ho on SpinLaunch, some aerospace engineers remain wary. One of the most significant critiques is that the rocket will have to endure extremely high forces inside the centrifuge—remember, we're talking 10,000 times the strength of gravity—while your typical rocket only bears forces five to seven times stronger than gravity at launch time.

"No rocket could survive this, nor could the electronics inside the rocket," Dan Erwin, an aerospace engineer at the University of Southern California, told Wired.

Meanwhile, a former SpinLaunch employee, who spoke to Wired on condition of anonymity due to nondisclosure agreements, said the centrifuge is an unsophisticated machine that "any average engineering team could put together."

So far, SpinLaunch has not made it anywhere near the cosmos, but instead has been working toward its first suborbital launch at a new test site in New Mexico, slated for this winter. Until then, we'll maintain a healthy dose of skepticism.

Source: Wired

You Might Also Like