Coronavirus is worrying electronics manufacturers, and everyday shoppers could end up seeing 'spot shortages' for certain gadgets if the situation worsens

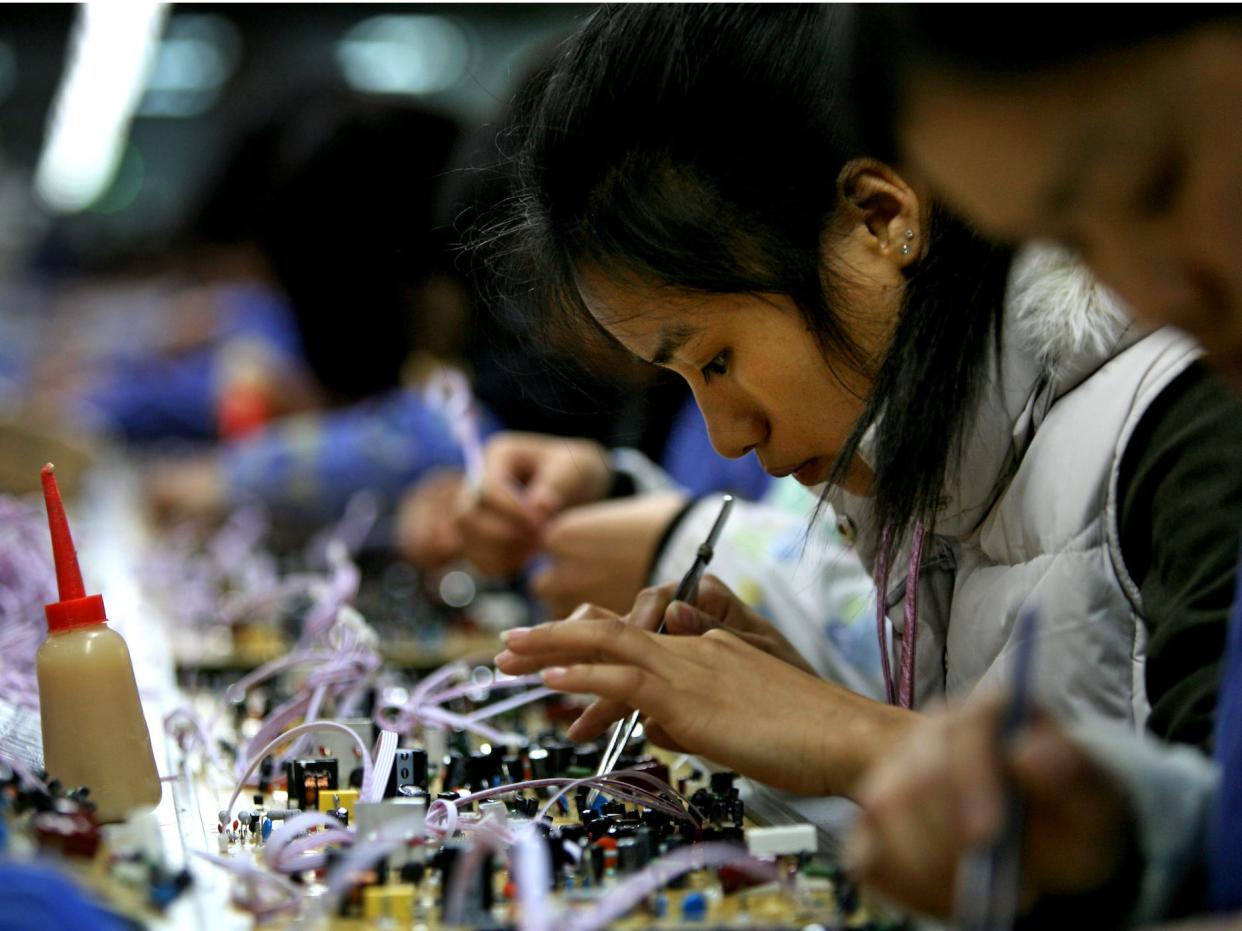

Reinhard Krause/Reuters

The coronavirus outbreak is causing electronics manufacturers major pain and delays, as suppliers based in China have struggled to keep factories running at full speed.

IPC, an electronics equipment trade organization, found in a February survey that a majority of electronics manufacturers are expecting delays of four to five weeks.

Suppliers and manufacturers are likely to bear the brunt of this crisis, and IPC chief economist Shawn DuBravac said consumers shouldn't expect empty aisles in the electronics department.

That being said, if the situation continues to worsen and delays build up, shoppers may experience inconvenient "spot shortages."

Even if factories become fully operational once more, many manufacturers worry about further delays and issues regarding shipping crucial components to the United States.

The coronavirus is sparking anxieties among electronics manufacturers, the companies responsible for assembling everything from computers to lawnmowers to power generators. And if issues with suppliers based in China and potential shipping bottlenecks aren't resolved in a timely fashion, everyday consumers in the United States could start to notice by the summertime.

Many of these electronics manufacturers based in the United States or Europe rely on certain components built by suppliers in China. IPC, an electronics equipment trade organization, ran a survey in February in which 65% of 150 participating electronics manufacturers and suppliers reported delays from suppliers due to the spread of coronavirus, which causes the respiratory disease COVID-19. The outbreak has claimed over 3,400 lives around the world.

So far, these delays appear contained enough, and manufacturers and suppliers will likely be taking on the brunt of the problem for the time being. But IPC chief economist Shawn DuBravac told Business Insider that, if the outbreak continues to drag the industry down into April, regular shoppers may begin to notice the effects firsthand.

And, even if the suppliers themselves become fully operational once more, manufacturers still worry over the strain put on what the IPC report described as "limited" and "finite" transportation networks.

"Where some uncertainty still lies is, even after manufacturing is back online, to what extent is it back online?" DuBravac said.

'The worst is yet to come'

Many of the electronics manufacturers in IPC's survey work across different industries and domains. These firms typically operate by acquiring necessary electronics components from different suppliers. Suppliers receive orders and ship the requested parts to the manufacturers. The components are assembled, and then the finished product is shipped on to the ultimate client, often a consumer-facing brand.

DuBravac said it's crucial that these manufacturers receive all the elements necessary to assemble a product at the same time, so that production can begin and the company can avoid a buildup of inventory.

William Hong/Reuters

But the international outbreak is throwing off that process. In its survey, the IPC found that around 65% of respondents were told by suppliers to expect delays of around three weeks in shipments due to the outbreak.

When it comes to the impact that the coronavirus will have on their business, 30% of survey participants admitted to being extremely concerned, while 54% said they were somewhat concerned. The survey ran between February 11 and February 16.

Electronics manufacturer representatives quoted within the story expressed concerns about experiencing delayed deliveries, shuttering product lines, and watching suppliers struggle to keep factories in China staffed.

"I believe the worst is yet to come," one anonymous manufacturer told IPC. "The Chinese local government is fully overwhelmed with this process and could take weeks to get flushed out for factory production starting."

And manufacturers' fears don't focus solely on delays stemming directly from reduced-capacity suppliers. DuBravac said that fears of a transportation bottleneck have arisen thanks to the outbreak. Scores of late shipments clogging shipping lines could stand to increase delays, even once factories are back online.

"We're worried that — even after manufacturing returns in China for these components that we use — there'll be further delays because transportation capacity will be maxed out," DuBravac said.

'Unprecedented delays'

Electronics manufacturers have a hand in making all sorts of products, meaning that the coronavirus could have a sweeping impact across industries. Such companies produce everything from electric lawn mowers, in-store control panels, cable boxes, and audio and video devices, and they are crucial to the automotive, aerospace, and medical sectors.

But DuBravac said it's too early to be able to tell exactly what products or companies could stand to get slammed the hardest.

"Because manufacturers have different suppliers, different inventory levels, and end up producing a different mix of products, it's not necessarily easy to identify that, let's say, all electric lawnmowers are going to be in short supply come July," he said. "Chances are some models might be, but they all are built differently by different manufacturers relying on different supply chains and different components."

The manufacturers themselves told the IPC that they believe delays will run longer than suppliers are saying. Over 55% said they anticipated delays of four weeks or fewer, while around 37% said they expected delays to take six weeks or longer. On the transportation side, the IPC report already cited "out of balance" transportation networks, highlighting reduced commercial air travel out of China, US ports brimming with "empty cargo containers," and limited traffic on "seaborne trade routes between China and other countries."

DuBravac said most companies' inventories can likely hold out until Easter. If the outbreak leads to delays of eight to 12 weeks, however, he said the situation would be "unprecedented."

Still, even if "unprecedented delays" come to pass and the situation fails to improve, DuBravac said most people in the United States will observe the issues in "very limited ways" starting around June and July.

'Oh, that's weird'

It's not as if shoppers will be confronted with abandoned electronics stores or aisles, even in DuBravac's worst-case scenario. Many of the manufacturing issues brought about by the coronavirus will be felt more on a behind-the-scenes, industrial basis. Others could result in irritating, but not life-upending, frustrations for customers.

DuBravac gave the instance of a consumer calling to replace a cable box and encountering a "spot shortage" prompted by the delays.

"The rep will say, 'Oh, that's weird. We can't install a new cable box. I'm sorry, I'm not sure why, but we've got a delay for two weeks,'" DuBravac said. "That's the conversation that I think the consumer will end up having."

Jianan Yu/Reuters

Some manufacturers told IPC that they were rerouting supply chains to avoid areas in China heavily affected by the coronavirus. DuBravac said many manufacturers are keen to establish a "dual-sourced" supply chain regardless of the outbreak, to keep from overly relying on one supplier or region.

But finding a new supplier can be easier said than done. Manufacturers are somewhat bound by the preferences of client companies, which may direct them to work with specific suppliers. And even if clients are open to new suppliers, oftentimes they will need time to "requalify" products to be able to work with parts sourced from new suppliers.

DuBravac said that in some sense, the current crisis proves how dynamic the supply chains of electronics manufacturers are, given that everyday consumers are unlikely to face too many issues buying electronics. He said he spoke to many firms working to problem-solve with clients and suppliers.

"There's conversation about how fragile the supply chain is, but in a study like this you really see how resilient it is — or at least the desire to make it resilient," DuBravac said. "I think that's one of the reasons why the consumer doesn't always feel the effect."

Read the original article on Business Insider