New details reveal what led up to Carowinds Fury 325 roller coaster pillar damage

State records obtained by The Charlotte Observer through a public records request provided new details Friday about what led to the high-profile break in the support beam of Carowinds’ largest roller coaster last summer — a problem that forced the amusement park to close the ride for over a month.

Fury 325 was shut down June 30 after a park visitor reported seeing a cracked beam as a cart full of passengers whizzed by. Carowinds inspects all of its rides daily but the visitor’s report apparently was how the park learned of the problem.

The viral video of the damage was posted on social media. No one was injured before one of the world’s tallest and most popular roller coasters was shut down.

The N.C. Department of Labor, which has jurisdiction over the Charlotte theme park that crosses the state line into South Carolina, released a series of documents to the Observer for a public records request from last summer for records related to the case.

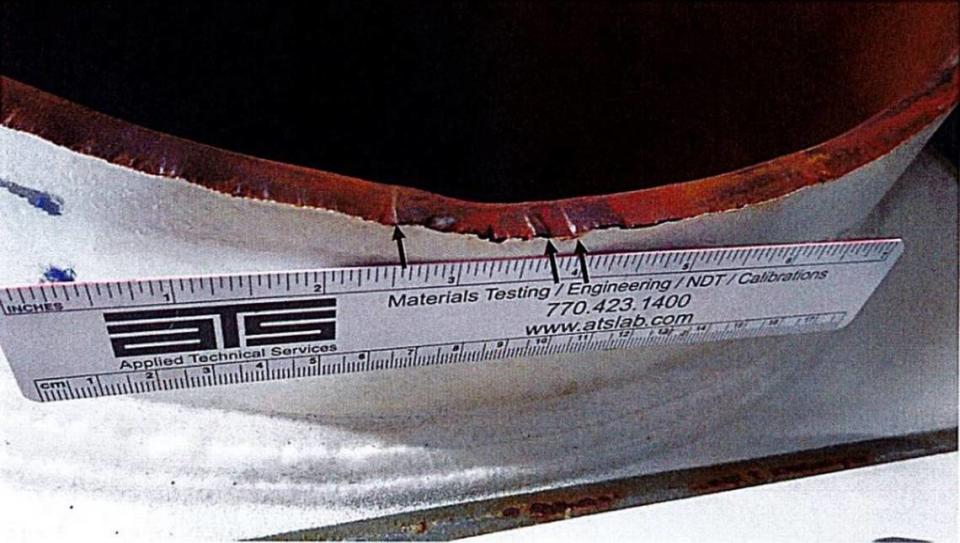

The cause of the coaster’s support column fracture was “the result of unidirectional bending fatigue,” according to the metallurgical failure analysis by Applied Technical Services in Marietta, Georgia, submitted Aug. 23.

The cause of the fracture had not been detailed until Friday.

How the roller coaster problems began

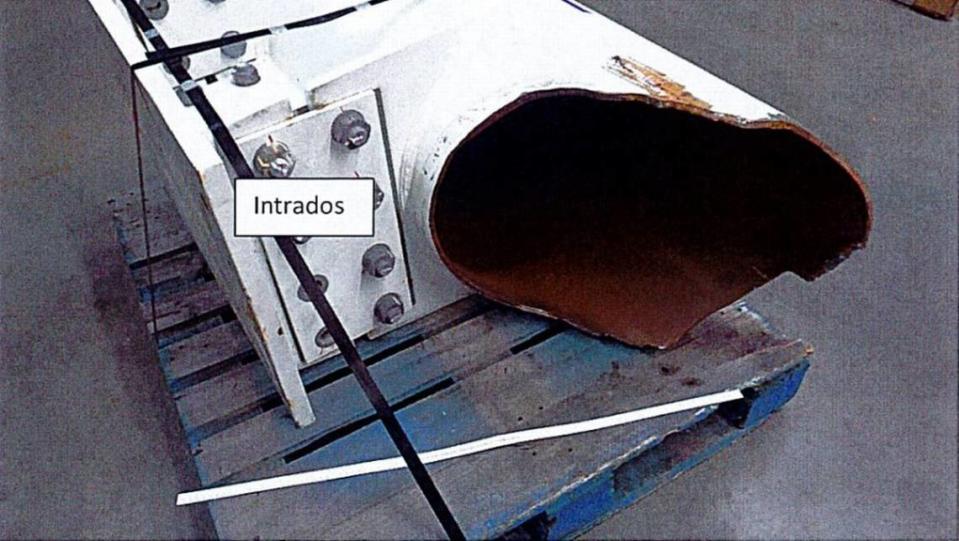

The fracture started at the toe, or edge, of the weld on the support beam’s joint then expanded to the circumference of the beam until the remaining cross-sectional area could no longer support the applied stress, the report found. And that led to the support column fracture.

The weld acted as a “stress raiser,” ATS found. While the weld was harder than the base metal, which is good for fatigue resistance, it was the V-shape of the weld itself that accelerated the fatigue, said Youxing Chen, assistant professor of mechanical engineering and engineering science at UNC Charlotte. He reviewed ATS’s report at the Observer’s request.

“This indicates the welds might need extra checks,” Chen said.

Certain marks on the weld, referred to as “ratchet” and “beach” marks, provided vital clues, Chen said.

He compared them to rings on a tree that show how it grows because they indicated where cracks in the metal started and stopped each time. Those cracks grew from the force of repetition in one direction as the 58,000-pound roller coaster train cycled once per minute.

Like bending a paper clip with the same force in the same spot several times, “it starts to weaken and break,” Chen added.

What the Carowinds files showed

Other key findings from the new documents include:

▪ The support beam, which was at a turn in the roller coaster, has been in service since Fury 325 opened in 2015. It’s life expectancy was over 50 years, according to the metallurgical report. Yet it lasted barely eight years.

▪ Last July, the state acknowledged that a second crack, or break, was found on the coaster. But state work orders in the filings from the Department of Labor show six cracks were found in other columns. All of those cracks, some found by drone inspections, were repaired by welding.

▪ Carowinds’ daily preventative maintenance reports submitted to the state from June 16 to June 29 show track inspections passed visual inspections and did not indicate concerns. The June 30 inspection was not included in the filings provided by the state, and the Labor Department referred all questions to Carowinds, which did not address that issue.

▪ A June 30 incident report and inspection by the Labor Department’s Elevator & Amusement Device Bureau shows the cause of the incident as “weld crack at top of weld and followed around the top of the column.” Corrective action is listed as “Carowinds will increase inspections of the structure.” No violations were cited by the state.

Carowinds response to release of state records

On Friday, Carowinds again refused to respond to questions about how its inspectors missed the fracture, or if anyone internally has been held responsible. Park officials also did not answer questions about the metallurgical report.

“Like all of our rides and attractions at Carowinds, Fury 325 is inspected daily by our staff during operation,” Carowinds said in a statement to the Observer on Friday.

The state inspected and approved Fury 325 for operation on Feb. 29, before Carowinds re-opened for the season last week on March 9, according to the park.

NC reports details more cracks

On July 28, 2023, repairs on several cracks were completed on two of Fury 325’s columns, according to a work order the park submitted to the state.

Two separate cracks about three inches apart were found on column 43 in the paint, one inspection report shows. After removing the paint, inspectors found one crack was two inches long and the other was three inches long. Each was about 1/8-inch deep. They were rewelded to roller coaster maker Bolliger & Mabillard specifications and retested.

A separate 1/4-inch deep four-inch crack also was found on column 43. It was rewelded and retested. And a crack was found in column 71. The 1/8-inch deep, two-inch long crack was rewelded.

The original pillar with the fracture that caused the ride to shut down was in column C47.

On Aug. 4, an ATS drone inspection detected cracks in unspecified columns. One report lists a crack on the left, three inches long, and another on the right that was two inches. The cracks were ground out, tested then welded to B&M specifications by Justin Morris of Melting Point fabricators.

A second report shows the drone also detected a three-inch-long crack that was ground out, tested and welded.

The work orders do not say where the cracks were found in the columns. “If you see a couple, that means you need to be very careful,” Chen said.

Roller coaster damage spotted by guest

The annual state inspection of Fury 325 on Feb. 23, 2023, found only minor issues related to signage, the Observer previously reported.

Fury 325 was closed on June 30, 2023, after the fracture was reported to park officials.

Though it wasn’t reported until the end of June, a photo from another visitor in a Facebook post appeared to show the crack beginning to form nearly a week prior, The Charlotte Observer reported at the time.

[PHOTOS: More images of Carowinds cracked roller coaster before it was shut down]

The state Labor Department annually inspects Fury 325 prior to the park opening for the season, along with daily checks from park employees who also inspect the rides in the park.

Park officials say many of its rides are designed and built by some of the world’s top ride manufacturers— which is what sparked concern about why this could’ve happened and how it was missed.

[When are Carowinds roller coasters like Fury 325 inspected for maintenance, safety?]

Fixing Fury 325

A new steel support pillar for Fury 325 was installed on July 14, 2023, by Bolliger & Mabillard. The park began extensive testing, including running 500 full cycles, on July 17.

Inspections and testing also were conducted by B&M and a third party, with the N.C. Labor Department’s Elevator and Amusement Device Bureau giving final inspections and approval to reopen.

Because of the ride’s structural failure, Carowinds said it was changing how it inspects rides daily, including using drone cameras to examine hard-to-reach areas.

About the Fury 325 roller coaster

The ride’s problems surfaced shortly after the park celebrated Fury 325’s 500,000th rider. in late June 2023.

The ride, which opened about eight years ago, is the tallest, fastest, longest giga coaster in North America that reaches up to 325 feet as fast as 95 mph. A giga coaster refers to rides with a height or drop of at least 300 feet.

The coaster has three 32-passenger open air trains.

Fury 325 has been named “Best Steel Coaster” by industry publication Amusement Today for eight years.

Based in Switzerland, B&M built Fury 325, as well as three other coasters at Carowinds. The 408-acre amusement park straddles the state line for the Carolinas.

Timeline of temporary closure after damage discovered

June 30, 2023: The Fury 325 roller coaster was temporarily closed down after a crack on one of the steel pillars that supports the track was reported following a viral video posted online of the damage.

July 3, 2023: N.C. Department of Labor’s Elevator and Amusement Device Bureau, the agency that oversees amusement park inspections, visited the park to investigate the crack.

July 5, 2023: Bolliger & Mabillard Consulting Engineers Inc., the Swiss company that designed and built Fury 325, sent a representative to Carowinds as state inspectors continue their safety review.

July 6, 2023: Park officials announced plans to remove and replace the broken column on Fury 325, along with extensive tests and inspections before reopening the roller coaster. The team shared that additional inspection procedures will be added at the park going forward.

July 12, 2023: Crews began work to remove and replace the original cracked pillar with a new column, which was completely installed two days later.

July 28, 2023: The state Department of Labor said a second “weld indication, which could either be a crack or a break” was discovered on the ride.

August 10, 2023: Fury 325 reopens to riders after extensive testing and a final inspection by the roller coaster’s manufacturer and a third-party testing firm.