EXCLUSIVE: H&M Group Ventures-backed Kintra Fibers Raises $8M

Kintra Fibers — known for its bio-based polyester alternative — raised $8 million in Series A funding, partners with Bestseller, Inditex, H&M and Reformation in a commercial pilot.

The Brooklyn, New York-based material sciences firm is backed by H&M Group Ventures, with Bestseller’s Invest Fwd funding arm, Fashion for Good, New York Ventures, Tech Council Ventures and Fab Ventures among the co-investors. Many notable female angel investors also participated in the Series A including Parade’s founder Cami Téllez.

More from WWD

“Our investment in Kintra Fibers’ technology is a compelling opportunity to transform the manufacturing process and contribute toward a circular and climate-positive future. What impresses us is that Kintra Fibers’ technology leverages existing polyester production equipment for critical manufacturing processes, such as resin and yarn production,” commented Erik Karlsson, investment manager at H&M Group Ventures, in a press statement. “This capability to scale quickly and cost-effectively is a major advantage for Kintra Fibers as they work towards their goal of reducing the fashion industry’s environmental footprint.”

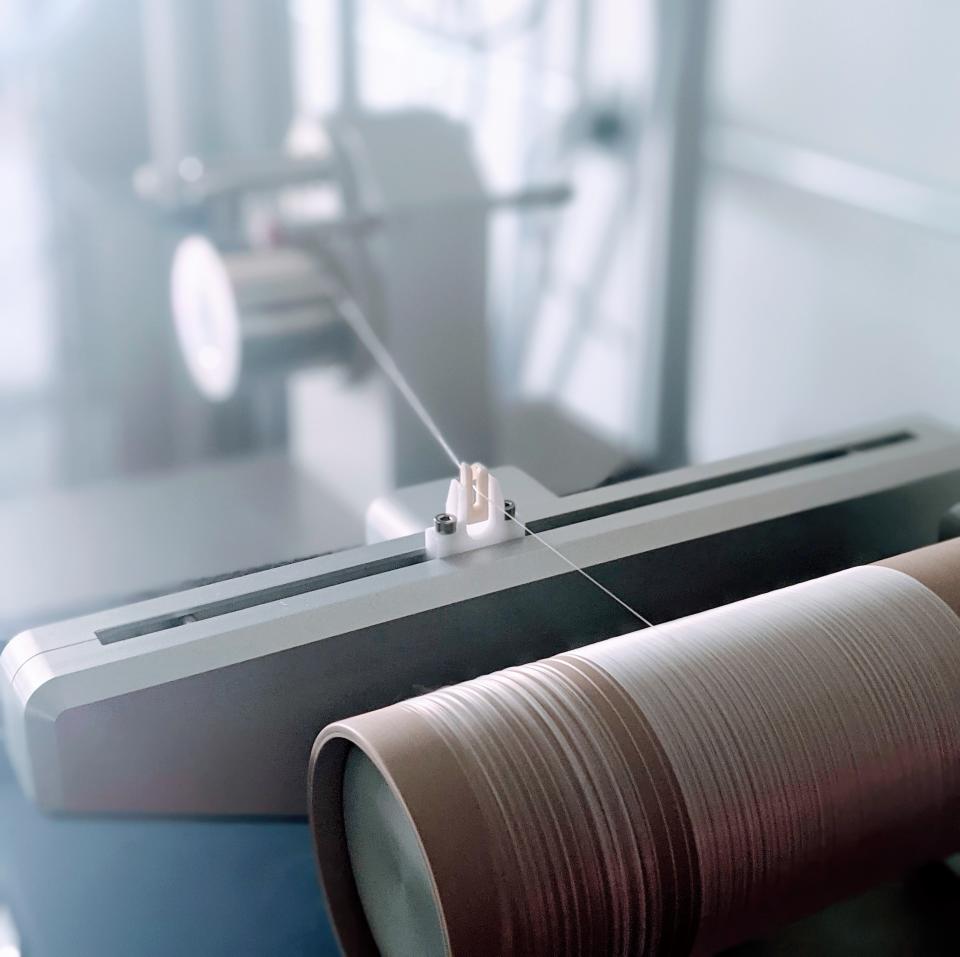

Unlike traditional polyester, which relies on fossil fuel-based inputs, Kintra sources 100-percent bio-based inputs derived from corn glucose to create its proprietary resin. Last year, Kintra joined Fashion for Good’s raw material cohort and shared its first fabric prototype. This year, Kintra is launching a pilot with a consortium of Fashion For Good brand partners, which includes Bestseller, Inditex and Reformation. “The super power of Kintra is that our material provides the strength of polyester, but is an order of magnitude softer,” said Alissa Baier-Lentz, cofounder and chief operating officer of Kintra, to WWD. Kintra has a stretch recovery of 10 to 15 percent, per its testing, making a use case for everything from knit sweaters to the woven outer layer on a puffer jacket.

There are other lures for industry investors. The Kintra fiber itself is biodegradable in an oxygen-rich environment (as Kintra yarns passed the ASTM D6400 / ISO 14855-1 tests for industrial compost) but can also be chemically recycled given it’s produced on the same equipment as polyester, though with a lower energy use per estimates from Kintra.

“What our LCA shows, unequivocally, is that with Kintra greenhouse emissions are reduced by 95 percent compared to traditional polyester,” Baier-Lentz reiterated. She said the Series A will be used for the material’s commercial milestones as well as its “manufacturing commitment” at its Brooklyn Navy Yard lab. “The goal of the first round of funding was to create our MVP, a stable, spinnable resin that can compete with polyester at an industrial setting,” she said.

With 250 kilograms of resin produced to date on a pilot line, Kintra is currently expanding to a commercial facility with the support of its Series A funding. The firm hopes to move into commercial scale and produce its first ton at the end of year. Baier-Lentz said Kintra will eventually reach price parity with recycled polyester and even virgin polyester when Kintra reaches plant-scale operations. At that point, agricultural waste and even algae can be used as feedstock.

Given that some 54 percent of textiles used today in fashion derive from fossil fuels, per Textile Exchange, Kintra and its industry funders are looking to rapidly scale the fiber.

“Innovations like this that help reduce our reliance on fossil fuel-based synthetics are essential to our sustainability efforts at Reformation, particularly our goal to be Climate Positive by 2025,” shared Kathleen Talbot, chief sustainability officer and vice president of operations at Reformation. “It’s on us as an industry to take an active role in scaling next generation solutions, like Kintra, that have the potential to power the future of fashion.”

Best of WWD