Here's What to Expect from Tesla's Battery Day

The EV automaker's public events are never not a spectacle, but this year Battery Day takes place amid a backdrop of a global pandemic that had temporarily shaken some markets' confidence in the continued near-term success of electric cars over the next two years. Those early worries about the car market have now largely evaporated, replaced by a bullish outlook as a new wave of EVs awaits on the horizon amid a small tsunami of electric pickup trucks hitting the market in the next two and a half years.

Tesla's Battery Day had originally been scheduled for April but had been delayed due to the pandemic, and will now take place on September 22 in conjunction with the company's annual shareholders' meeting in Palo Alto.

What can we expect from Battery Day?

One prominent piece of battery tech Tesla is believed to be working on features much greater energy density than existing batteries, and could use silicon nanowire battery technology to achieve this. The automaker posted an image on its own site announcing the event, with what appeared to be images of silicon nanowires, leading some to take that as a hint of what it had in store for Battery Day. Tesla CEO Elon Musk invited more speculation about possibally using this technology with a tweet, suggesting a battery with much higher energy density was on the horizon.

"400 Wh/kg *with* high cycle life, produced in volume (not just a lab) is not far. Probably 3 to 4 years," Musk tweeted in August.

400 watt-hours per kilogram would represent a substantial gain for energy density in EVs, which now hovers just above 230 Wh/kg. The payoff for consumers would be longer vehicle range and smaller battery size.

Of course, by Musk's own admission this technology is still somewhat far on the horizon, not headed into cars next year, but it's among the items expected to be discussed during Battery Day.

Another piece of tech with buzz heading into Battery Day is Tesla's cooperation with China's Contemporary Amperex Technology Ltd. on a "million mile battery" that could use lithium-ion phosphate instead of cobalt. The million mile part refers to a potential battery's longevity, seeking to allay long-standing fears of EVs becoming too replaceable at a certain point in their life cycles to be fitted with new batteries, which are still pricey. But Tesla's cooperation with Contemporary Amperex Technology Ltd. is believed to be aimed at driving down the cost of battery production, allowing the automaker to (potentially) skip the pricey cobalt metal in EV batteries and offer lower starting prices for its vehicles.

Several battery developers are now at work at finding replacement substances for battery composition to make production less expensive while making the batteries themselves significantly lighter, thus driving down their production costs and making EVs less expensive. Finding replacements for traditional metals used in EV batteries would also make their manufacture less reliant on mining metals, which poses a significant environmental cost.

Of course, a battery that could last an actual million miles is perhaps too much of a good thing for automakers. For one thing, achieving this mileage greatly exceeds how long people usually keep cars, and making something that's too long-lasting doesn't really work well with automakers' goals of selling you a new car every few years.

Yet another long-awaited development could see Tesla drop Panasonic as a battery supplier and begin manufacturing its own batteries. This potential development has been talked about for years but became a point of contention relatively recently, with the Model 3's painfully slow production ramp-up that had struggled along for months as Tesla experienced several production bottlenecks related to battery pack assembly problems. Some reporting suggested that many battery packs were being hand assembled after various automation failures. As a result of these issues, automation was scaled back in the early months of Model 3 production, causing the automaker several months of embarrassingly low production figures.

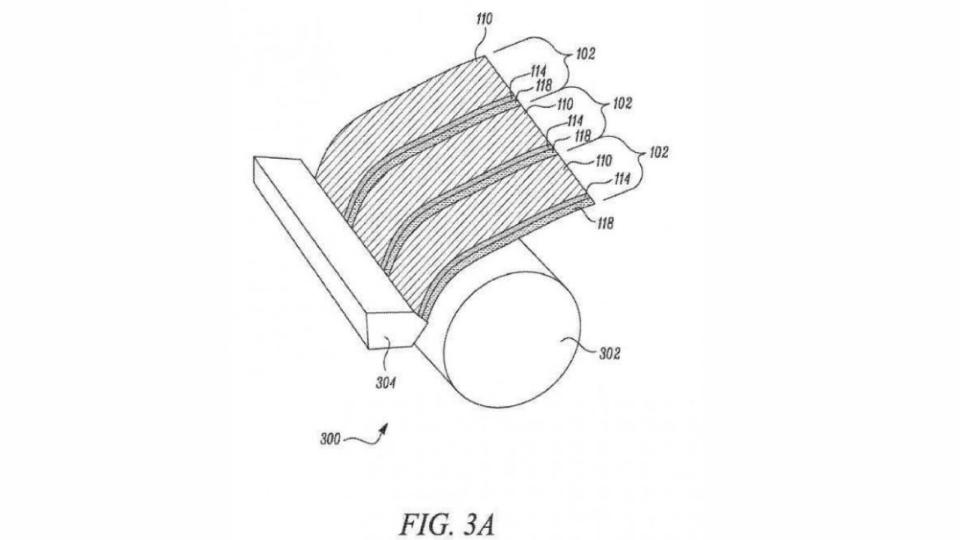

A more obscure development, one that Musk has hinted at in recent months, could also be a tabless battery cell design. Such a design would eliminate the cathode and anode tabs of today's cylindrical cell can, for which Tesla has filed a patent earlier this year.

"Current cells use a jelly-roll design in which the cathode, anode, and separators are rolled together and have a cathode tab and an anode tab to connect to the positive and negative terminals of the cell can," the patent states in part. "The path of the current necessarily travels through these tabs to connectors on the outside of the battery cell. However, ohmic resistance is increased with distance when current must travel all the way along the cathode or anode to the tab and out of the cell. Furthermore, because the tabs are additional components, they increase costs and present manufacturing challenges."

Tesla's proposed design would see first substrate, the inner separator and a second substrate rolled around the cell can, thereby reducing the amount of parts in a battery pack. This design has been nicknamed the "biscuit tin" due to the way it looks. But it remains to be seen whether this method of building battery cells is ready for production, and just how much production cost could be saved by implementing it.