Hooked on History: Clay industry spurred growth of Twin Cities in early 20th century

The Twin Cities have long prided themselves on being the "Clay Capital of the World," and Uhrichsville and Dennison would never have grown as fast as they did in the early years of the 20th century without the clay industry.

Between 1903 and 1924, more than 10 clay plants opened in the Twin Cities district, which included Midvale, Gnadenhutten and Lock Seventeen.

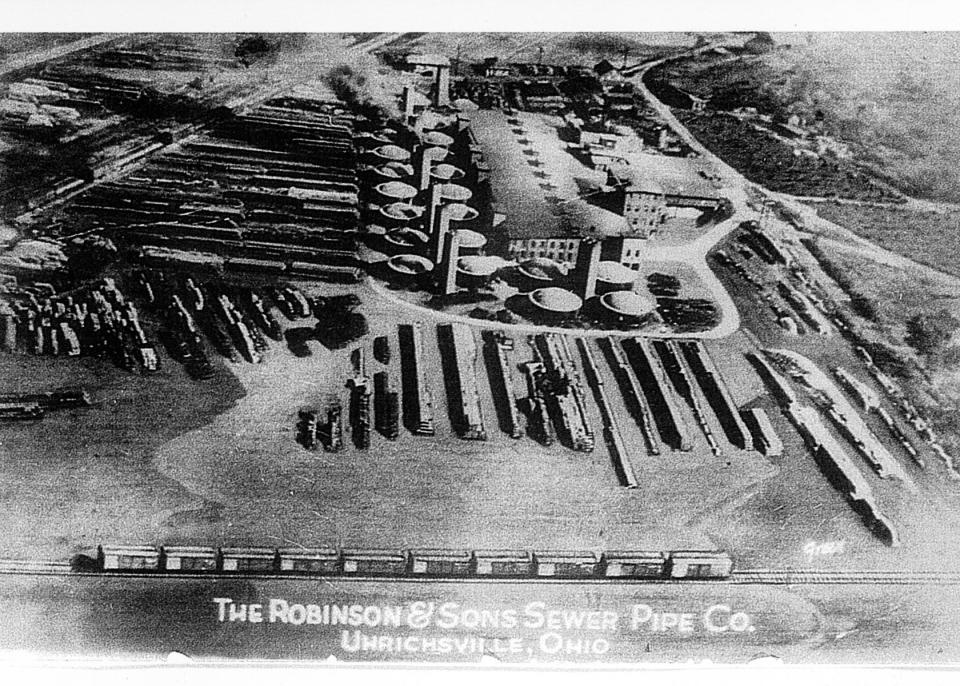

The first plant was the Robinson-Graves Sewer Pipe Co.’s works, located on the Baltimore & Ohio Railroad in Roanoke. The company grew out of the meeting of Andrew Robinson and Charles L. Graves in 1902.

Andrew Robinson was a native of Scotland who emigrated to America in 1885. He came to Uhrichsville when the Diamond Fire Clay Co. opened in the 1880s. When the Uhrichsville Fire Clay Co. was organized, he became a stockholder. He managed that plant until it was sold to the American Sewer Pipe Co. in 1900. He then managed the Royal sewer pipe works in Midvale.

Graves, a native of Michigan, came to Tuscarawas County in 1902 when he became manager of the Hiawatha Coal Co.

The Robinson-Graves Co. was organized on March 13, 1903, and the plant went into operation on July 25 of that year.

Graves eventually left the company, which then became known as Robinson & Sons Sewer Pipe Co.

Thomas Jefferson Evans, a prominent Uhrichsville banker, entered the clay industry in 1906 when he established the Evans Pipe Co. A plant was built south of Uhrichsville on the road leading to Newport.

Evans died in 1920, but his sons, Eugene and Thomas Jefferson Evans Jr., continued the operation.

In 1922, the plant was expanded by 40%, making it equal in size to the Royal plant at Midvale. According to the Brick and Clay Record, the expansion included 10 36-foot kilns and buildings that provided 50,000 feet of additional floor space.

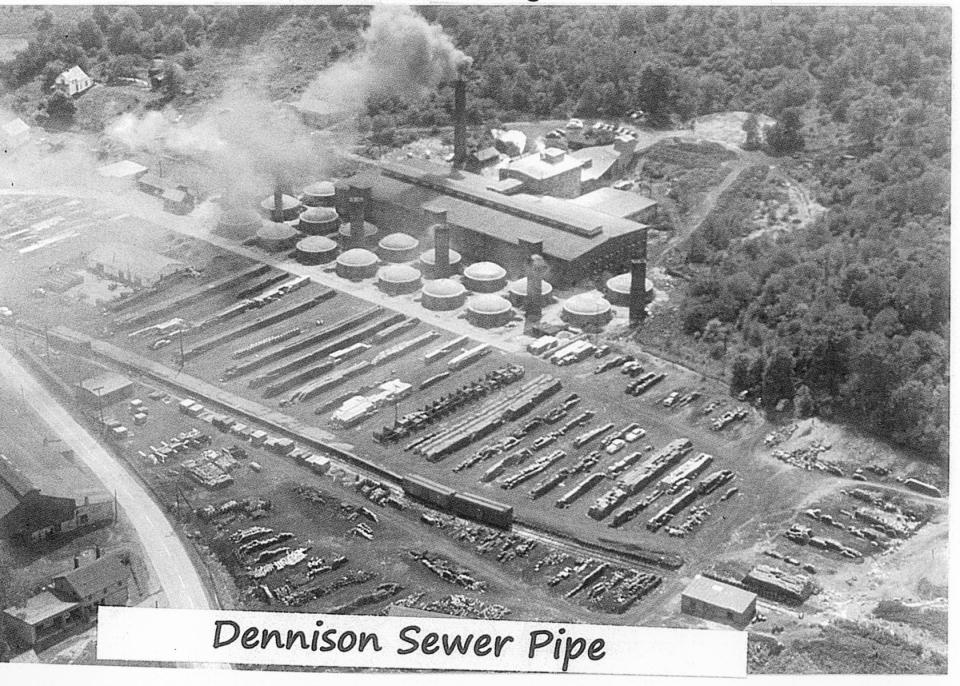

In 1911, two more clay plants opened in the Twin Cities — the Dennison Sewer Pipe Co. on Stillwater Avenue in Dennison and the Uhrichsville Clay Co. on what is now U.S. Route 36 near the Tuscarawas River in Warwick Township.

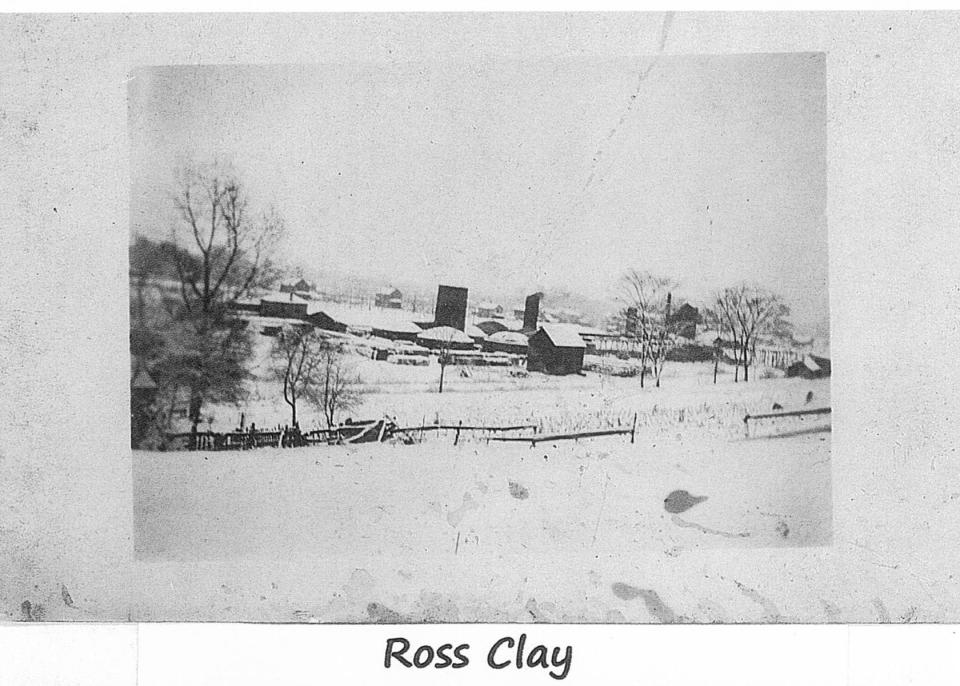

On June 19, 1914, the Ross Clay Products Co. was organized by George Ross, G.E. Calhoun, E.A. Lukens and others. It opened its first plant off of what is now Pleasant Valley Road in Union Township, about two miles east of Dennison.

The Ross family had been long involved in the local clay industry.

George Ross was born April 21, 1845, in Shilden, England. His father, John Ross, died when he was 10 years old, and George was put to work in the coal mines.

“There were no laws governing the age a child could start working or the number of hours a day he should work,” his daughter Alma later wrote. “Sometimes it would be two weeks at a time he would not see daylight as he would enter the mine before daylight and it would be dark when he would come out in the evening.”

By the time he was a young man, Ross had saved enough money to pay his fare to America, a place he had dreamed of for many years. He found work in the mines in Scranton, Pa.

After several years, he returned to England to marry his sweetheart, Marion Elizabeth Metcalf. They went back to Scranton, where a daughter, Eva, was born. When the baby was less than a year old, Marion died. George Ross found it difficult to care for his infant daughter, so he took her to England to be raised by the Metcalf family.

Ross returned to America and married a widow, Mrs. Elizabeth Davis, in 1877. He then sent for his daughter living in England.

George and Elizabeth had five children — Elsie, Alma, George A., Charles E. and David Rayne.

The family lived in the Steubenville area from 1878 until 1886, when they moved to Uhrichsville. George Ross, because of his knowledge of mining and clay, had been asked to go to Tuscarawas County by men interesting in the clay industry to do some tests on clay in the Uhrichsville area. The tests proved satisfactory, and the Diamond Clay Co. was organized. Ross open the first clay mine here.

Ross helped organize and served as president of the Advance Fire Clay Co., which the family owned until the plant in Roanoke was sold to the Belden Brick Co. of Canton on Dec. 20, 1917. Belden Brick had been selling the output of the Advance since 1909.

When George Ross organized the Ross Clay Products Co. in 1914, the time was right for another sewer pipe factory in the Twin Cities.

“Clay sewer pipe was in demand,” Mark E. Ross, George Ross’ great-great grandson, later wrote in a history of the company. “At the time, there was not much other competition. Plastic pipe had not been developed yet and concrete pipe did not have the strength qualities worked out at the time to be competitive with clay pipe. There was a market for this product.

“The timing was right. Through World War I and into the early to mid 1920s, it was booming times for industry in the United States, and construction demanded lots of clay sewer pipe. And for quality and longevity, it would still be hard to top clay pipe. My personal experience on construction projects in railroad yards when old clay pipe is

being removed that I know is over one hundred years old, it comes out of the ground (if done so carefully) looking as good as the day it was laid. It would probably last forever.”

George Ross Sr. died at his home in Roanoke on Sept. 24, 1919, after having been ill with bronchial pneumonia for nine days. He had retired from active work in 1918.

The Ross Clay Products Co. continued to prosper and expand in the years that followed. In 1922, the stockholders increased the stock of the company from $100,000 to $250,000 to build a new mine and factory on a more than 200-acre tract at Lock Seventeen. The new plant went into operation about a year later.

In 1916, Dr. E.A. Wolf and Theodore Lanning organized a clay company and built the Wolf-Lanning plant just east of Dennison on the Pennsylvania Railroad.

The early 1920s saw a further expansion of the clay industry as the economy boomed after World War I.

In the spring of 1922, the Stillwater Clay Products Co. was organized by H.B. Galbraith, H.D. Westhafer, J.A. Pearch, D.K. LaPorte, H.B. Cameron and J.A. Barkley. The company purchased more than 100 acres from the Walnut Coal Co. along the Baltimore & Ohio Railroad between Uhrichsville and Newport to build a clay plant. It was going to manufacture sewer pipe and flue linings.

At the same time, the Romig Clay Products Co. was formed with E.R. Van Ostran as president, John Gardner as vice president and P.A. Romig as secretary-treasurer and general manager. The company purchased 54 acres from John W. McCreery, who had a farm in Warwick and Rush townships, southeast of Gnadenhutten. It later became the Larson Clay Pipe Co.

As the 1920s came to a close, the sewer pipe industry hit upon hard times, and there were rough times ahead during the Great Depression.

This article originally appeared on The Times-Reporter: Clay industry spurred growth of Twin Cities in early 20th century