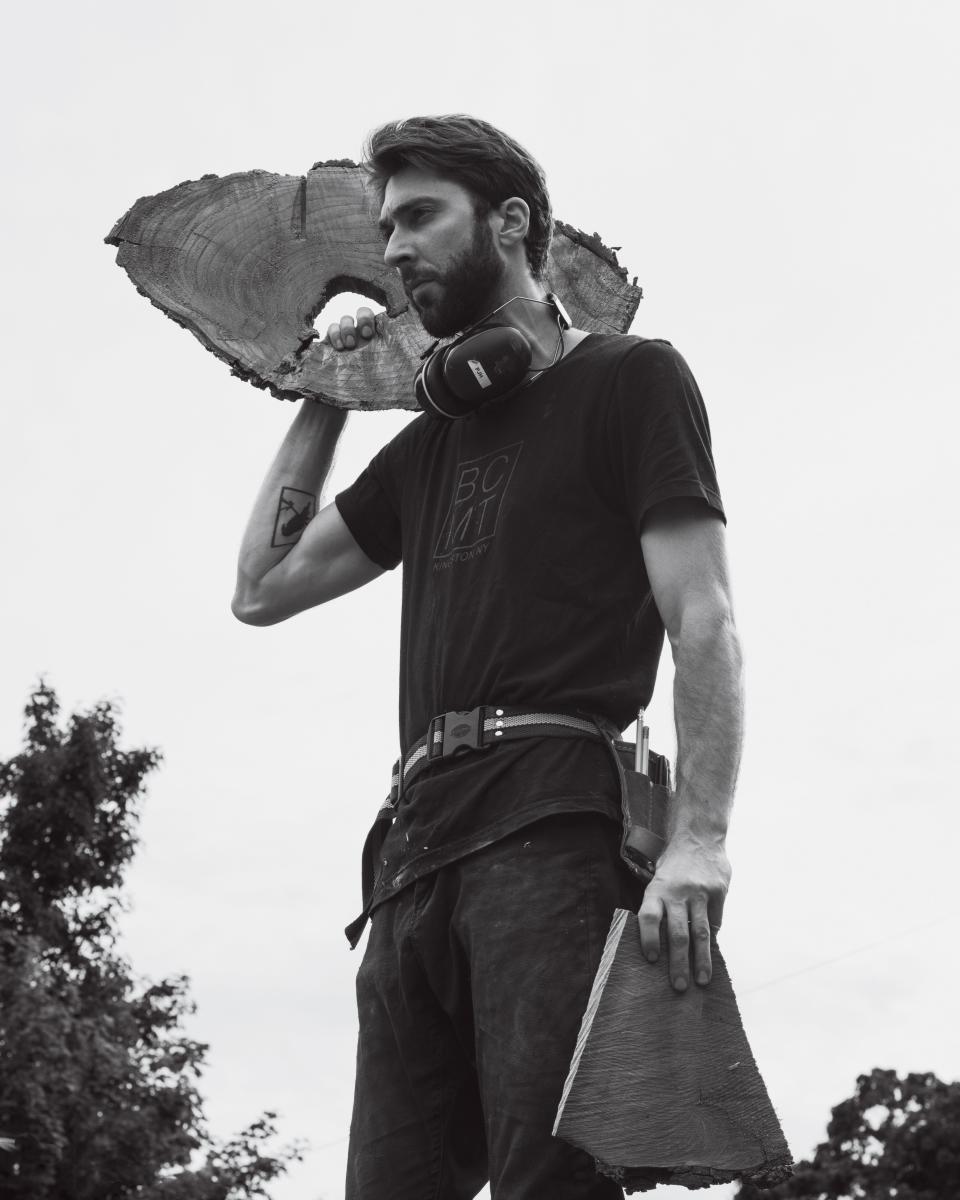

Meet the Wood Worshippers of Blackcreek Mercantile & Trading Co.

Joshua Vogel does some unusual things with his hands when he speaks. Not like the gesticulations of an exuberant Italian or the aggressive chops of a battle rapper. Vogel, a highly skilled woodworker, appears to sculpt the air around him. When describing the peculiar shape of a bowl he's turned out of a beech burl, or what makes a mortise and tenon the strongest way to join two pieces of wood, he gestures forms that hang there in a fog of sawdust. He finds the shapes of things that don't yet exist.

In a 10,000-square-foot factory in Kingston, New York, Vogel and his team of 11 employees make expertly crafted, impossibly simple, stunningly beautiful furniture under the name Blackcreek Mercantile & Trading Co. He and his partner, Kelly Zaneto, have built up their business slowly, beginning with, believe it or not, cutting-board oil. Today it is one of the most highly regarded wood-furniture companies in the world, and its products can be found at premier home-and-design stores, including March in San Francisco and The Line in New York City.

“I wanted to have a cottage-industry business, something where I could get up, make something, pay the bills, and have some creative space.”

Vogel's journey began long before he made his first bowl, the way so many epic American stories do, with our hero living as cheaply as he could while trying to find his path. He had enrolled at the University of Oregon, in Eugene, but couldn't afford both tuition and rent, so he slept in a Volkswagen bus. He briefly studied architecture before dropping out and making his way to Mexico. “I was like, ‘Fuck this,’ ” Vogel recalls. “And somewhere along the drive back, this guy called and was like, ‘Come to New York.’ ” That guy, Tyler Hays, a fellow craftsman from Oregon, soon became his business partner.

Vogel had learned his way around a woodshop while in Eugene. “I built a pretty fancy sling chair for myself,” he says. “And I saw a guy demonstrating the bowl lathe. And the very next day, I was like, ‘This is for me—I want to get a piece of wood and go learn how to do that.’ I was in love with that lathe. As soon as I quit and moved to New York, I thought, All I need in my life to be happy is a place to live and a lathe. That's it.”

It took ten years, but he eventually got the lathe. Vogel made his way to Brooklyn, where he and Hays started with a workshop in Greenpoint, producing handcrafted furniture under the name BDDW. (They thought the brick smokestack on a nearby building had the letters BDDW on it but later realized it was actually EDDW.) It didn't take long to figure out that clients weren't going to visit their gritty, industrial corner of Brooklyn and that they'd need a showroom in Manhattan if they wanted to sell anything. So they opened a shop just off Freeman Alley in 1997, predating by several years the hipster-lifestyle boom of haberdasheries, barbershops, and farm-to-table dining that would take place on that exact street and throughout the rest of the Lower East Side. By 2000, when BDDW moved to Crosby Street, the business was thriving—a single dining table could cost upwards of $50,000—but Vogel soon found himself spending more time managing operations and less time doing what he loved: turning bowls on the lathe. So he left.

“I wanted to have a cottage-industry business, something where I could get up, make something, pay the bills, and have some creative space,” Vogel says. That's what led to the creation of Blackcreek Mercantile & Trading Co. cutting-board oil, a food-safe mixture of bee propolis (the glue honeybees produce to maintain their hives) and cold-pressed lemon or rosemary. It sold well. Extremely well. And so people started to ask, “Why don't you make cutting boards?”

I don't want to fucking sell cutting boards, Vogel thought. All around him, designers were outsourcing to China in order to survive producing goods like that, and he wanted to make things himself. “The prevailing attitude was you cannot produce anything in the States anymore if you're gonna try to make a profit on it,” he says. But he became determined. “If I go to the mechanic, and that guy charges 70 bucks an hour to fix my car because he's got this workshop and expertise, why can't I? If it's gonna take me an hour and a half [to make a cutting board], why can't that be worth a hundred bucks?” It worked. “We stuck to our guns with that, and I tried to get a lot better about what I could do in an hour.” BCMT now sells cutting boards and butcher blocks that cost anywhere from $120 to $585.

And if you find it difficult to get excited about a cutting board, or to see how something so simple and plainly functional can feel as special as a pair of bench-made shoes and bring you serenity the way a work of art can, then you should plan a trip to upstate New York.

This September, BCMT opened a new showroom in an old brush factory in Kingston. The 1,700-square-foot space shows the full range of Vogel's practice, from salad utensils to dining-room tables. “I think about almost all of it as sculptural woodwork,” he says, but it all exists in some part of the spectrum. “I'm going between functional work to gestural work on the other end.” Most of the furniture is made from thick planks of wood. The footstools weigh nearly as much as concrete blocks and are supposedly sturdy enough to support the weight of a car. They are dyed a handful of natural shades—white, blond, gray, black—using colors derived from the tannins found within the wood. Vogel has developed an elementary system of shapes and angles for tables and benches that can be scaled up or down while adhering to his simple principles of reduction and sturdiness—there's nothing extraneous, and it's all built to withstand anything short of the apocalypse.

“There’s a recognition we have with wood. A natural root-ness. It keeps moving. And if you break the rules of construction, it will start to tear itself apart.”

Where Vogel gets experimental is with what he calls the gestural works—abstract clusters of carvings, arborous oddities turned into vessels, psychedelic spoons. Sometimes the most striking move is merely about scale and distorting preconceived notions of use. For example, visitors to BCMT often ask what Vogel's giant bowls are supposed to be. “I love the idea that at [normal] size, you know what it's supposed to be used for: ‘I can put chips in there.’ You don't have to change the shape of it at all, but just grow the size and it becomes absurd.… It's very poetic for me to find those points of departure where this does not make sense anymore.”

It can be hard to tell during our conversation whether we're talking about wood or about something existentially more significant, more human. People and trees, after all, are both temporal beings fashioned from organic matter, each one unique, grown from seed, vertically inclined, with a finite life span subject to all manner of disease and degradation. The way he sees it, this is what attracts us to wood in the first place. It's a living thing, just like us. It breathes like we do. It changes with time. It can be hard or soft, useful or not.

“There's a recognition we have,” Vogel says. “A natural root-ness. It keeps moving. It was alive—it still is alive. And if you break the rules of construction, it will start to tear itself apart.”

Noah Johnson is a GQ Style Senior Editor.

This story appears in the Holiday 2018 issue of GQ Style with the title “The Wood Worshippers of Blackcreek.”