Microchips, medicines and metals: Britain looks to revive its industrial base

- Oops!Something went wrong.Please try again later.

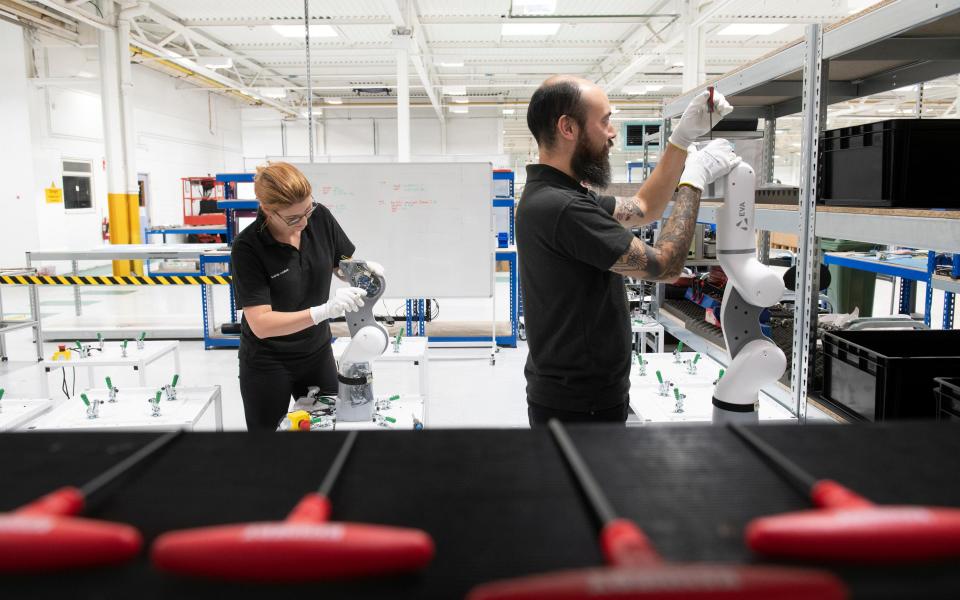

Robots might be ultra-efficient, but they are also frustratingly reliant on all-too-fallible humans.

Brian Palmer, chief executive of Blyth-based robotics company Tharsus, knows this only too well after being repeatedly let down by suppliers of crucial components.

“There's a new phrase I've not heard before, which is “de-commit”. So maybe a week or two before something's due to land we get a “de-commitment” - the supplier de-commits to supplying it,” he says.

Contracts “don't seem to matter”.

Delays, he says, are becoming routine: “One of our motor suppliers who we also buy drives from - one of the largest in the world - just increased lead times from six to 26 weeks two or three weeks ago.”

For Palmer, supply problems range from basics, such as resistors and capacitors, through to microchips - a shortage of which has hit production in industries such as car manufacturing across the world.

Even fairly common steel products are now in short supply, he says: “Your mill prices are almost doubled on mild steel and on speciality steel, maybe up to 200pc. Their availability is a challenge as well.”

Palmer is now trying to make his business more resilient by holding at least two months of stock, but even that may not be enough.

Calls are now growing for the UK to ramp up its domestic supply chains to help companies like Tharsus avoid global shortages.

One area that could benefit is semiconductors. Soaring demand for consumer gadgets combined with the after effects of pandemic lockdowns in Asia have combined to produce a global shortage in the vital components used to manufacture everything from speakers to cars.

Tony Danker, director general of the CBI, argues that Britain cannot simply try to build a domestic alternative to such a highly specialised global industry.

“If the goal now is to build self-sufficient islands, I don't think that is a good outcome, I don't think it is a highly productive outcome, and it is a terrible reversal of the benefits of global trade,” he says.

“We’ve got a semiconductor cluster in South Wales to be proud of, but the scale of the challenge is a global one.”

Trying to cut back on international trade could also harm local prosperity. The risk is that once trust starts to break down, governments feel they have little choice but to step in to boost domestic production.

The steel industry - strategically important for defence but also wider manufacturing and construction - is already in the middle of a global trade war.

The EU imposed tariffs on imports after the US fired up protectionist barriers. Britain is due to review these “steel safeguards” this week.

Richard Warren at industry group UK Steel says the measures must be temporary, but that for now “if the UK Government was to get rid of them or weaken them, it would really impact on the sector’s ability to recover” from the pandemic.

“We would be one of the very few completely open markets in the world. The UK is a small market, and it can be flooded,” he warns.

“The EU is not going to provide free and open access to its markets. The US isn’t going to. It may sound parochial, but why should the UK, if they are not reciprocating?”

Kallum Pickering, economist at Berenberg Bank, says there is a risk of spiralling protectionism, destroying the benefits of free trade for the sake of perceived resilience.

Once one country pulls back from globalisation, others end up doing the same.

“If this is a symptom of widespread fears about global supply chain security, then what we have is another reason to be worried about globalisation going into reverse,” he says, adding that “the whole global trade system is built on trust”. Once trust goes, then free trade gives way to a scramble for resources.

“The lesson of history is pretty clear - trade is a much more optimal situation than some kind of mercantilist-style approach.”

Trust is clearly lacking in pharmaceuticals, as pandemic-panicked politicians around the world hit export bans on key medicines and crucial components.

The net result was a threat to the world’s ability to create drugs and vaccines.

Martin Sawer, executive director of the Healthcare Distribution Association, notes that the concentration of manufacture of active ingredients in key drugs often in just one or two factories in India or China makes supplies vulnerable to a natural disaster, fire or political or regulatory shift.

But liberalisation, not nationalism, is the way to ensure resilient supply, according to Rick Greville at the Association of the British Pharmaceutical Industry.

“It is not practical to think each individual country can have the manufacturing ability to supply all medicines within their country. That isn’t feasible,” he says, calling moves to reshore manufacturing or to stockpile drugs “simplistic”.

“But what is feasible is for manufacturing sites to be selected satisfying various criteria, and one important criteria is the ability to move that medicine to countries which need to be supplied.”

That means governments which commit to open trade are more likely to attract a factory to their shores than ones which impose export controls to secure short-term supply.

Businesses themselves might be driving the shift to a more resilient economy more than governments ever could.

Duncan Brock at the Chartered Institute of Procurement and Supply says companies are reviewing supply chains to minimise disruption, and address consumer concerns over issues such as the environment and forced labour.

“Buying everything from one sole supplier in China has been exposed as something that is not ideal,” he says.

Once reliability and sustainability are factored in, shopping locally might even be better value.

“Is buying local more expensive? The price might be more expensive, but once you add in freight, transport, insurance, stockpiles and everything else, the total cost might be the same or cheaper,” he says.

“You might have something [from China] which is cheap, but if you cannot get it then it is extremely expensive.”