MIT Scientists Cooked Up a Mind-Blowing Way to Shrink Objects to the Nanoscale

Maybe it's not the stuff of Marvel's Ant-Man or Honey I Shrunk the Kids, but MIT scientists have mastered a mind-blowing way to shrink stuff by fabricating nanoscale 3D objects of nearly any shape.

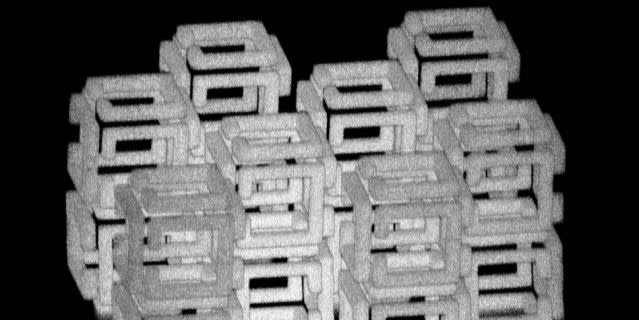

Called implosion fabrication, “it’s a way of putting nearly any kind of material into a 3-D pattern with nanoscale precision,” says Edward Boyden, a professor of biological engineering and of brain and cognitive sciences at MIT, in a press statement. Boyden says everything from metal to quantum dots to DNA strands have patterns that could fabricated in the extreme miniature.

While there have been ways to fabricate 3D structures in miniature before, they've been slow and not particularly effective. Scientists needed to add layer after layer upon 2D nanostructures-or be satisfied with simple self-sustaining shapes like pyramids. That's cool, but such an approach cannot build complex structures like DNA helixes or hollow tubes. If nanofabrication wants to reach its full potential-adding microscopic robotic particles to cancer drugs, for example, allowing to target cancer cells with greater accuracy-it must be able to work with complicated shapes.

The MIT process takes a technique currently used to make images of brain tissue larger and reverses it. How? Well, the brain tissue expansion process embeds tissue into a hydrogel and then expands it, which allows for high resolution imaging with a regular microscope. In this backwards version, a large-scale object is placed within a hydrogel (the more absorbent the better). The MIT scientists used a material made up of polyacrylate, which is typically found in diapers. The polyacrylate was then bathed in molecules of fluorescein, an orange dye with a yellow-green fluorescence that's commonly used as a scientific marker. These markers act as anchors that can bind to other molecules scientists might add.

“You attach the anchors where you want with light, and later you can attach whatever you want to the anchors,” Boyden says. “It could be a quantum dot, it could be a piece of DNA, it could be a gold nanoparticle.”

With the fluorescein in place, scientists then add an acid that hinders the negative charges in the polyacrylate gel. Without these negative charges, the gel no longer repels itself on a molecular level and begins to contract. This technique can create a 10-fold shrinkage in each dimension, equal to a 1,000-fold reduction in volume.

“People have been trying to invent better equipment to make smaller nanomaterials for years, but we realized that if you just use existing systems and embed your materials in this gel, you can shrink them down to the nanoscale, without distorting the patterns,” says lead author and grad student Samuel Rodriques.

The potential applications for implosion fabrication are widespread, according to the MIT team. Specialized lens could be shrunk down to better study the fundamental properties of light. Smaller lens could be made for cell phone cameras or microscopes. Farther into the future, the process could even be helpful in creating nanorobots.

“There are all kinds of things you can do with this,” Boyden says. “Democratizing nanofabrication could open up frontiers we can’t yet imagine.”

Source: CNN

('You Might Also Like',)