NASA picks Austin-based Icon to build 3D-printed structures on the moon

An Austin company will play a key role as NASA aims to return to the moon and establish a base camp on the lunar surface.

Icon, the Austin-based construction company that uses giant 3D printers to build houses and other construction projects, has been awarded $57.2 million by NASA for the development of a construction system to build structures on the moon.

Icon was co-founded by Jason Ballard with the goal of reimagining construction through its Vulcan 3D printers. The company says its 3D printing technology is faster, less expensive and has a wider range of options than traditional construction. The startup has already built dozens of homes and structures on Earth — it printed its first home using 3D technology in 2018 — and has worked with NASA previously.

"The first construction projects ever done on another world will be run out of a mission control here in Austin, Texas, which is pretty wild," Ballard said. "We're hopeful we can make Texas proud."

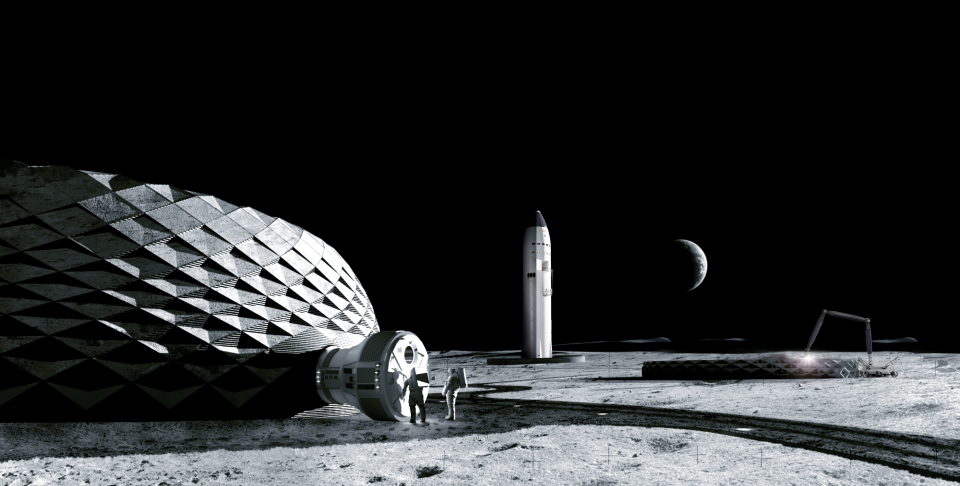

The Icon contract is part of NASA’s Artemis program, which is intended to return astronauts to the moon by 2024, including the first woman. Icon's advanced hardware and software will be hitching a ride to space aboard a lunar gravity simulation flight with the goal of building out the first-ever construction on a celestial body. The ultimate aim is to build a structure that astronauts can live and work in.

The Artemis program aims to establish a sustainable human presence on the moon by 2028, do research on the lunar surface and lay the foundation for private companies to build a moon economy. Artemis also aims to be a step toward humanity's "next big leap" to send humans to Mars.

Icon's construction system for the mission, called Olympus, will work similarly to the 3D printers on Earth, using computer-aided design to create three-dimensional objects through a layering method. To save costs and the number of materials needed to ship as well as account for the harsh environment, moon material will be used rather than concrete, which is also water-based and unable to be used on the moon.

"We have the strong commitment to what's called ISR, in-situ resource utilization, or as they would sayin East Texas, living off the land," Ballard said.

More:Austin-based Icon's newest project will simulate life on Mars, pave way for NASA's 'next giant leap'

'We hope just to be worthy'

Ballard said landing the NASA contract has been “unbelievable” and said it’s been exciting to watch NASA launch Artemis One in recent weeks. The space agency launched an Orion spacecraft and broke a new record for the farthest distance from earth a spacecraft designed to carry humans has ever traveled.

“Just walking around with my kids, pointing at the moon, it's crazy. It changes the way you look at the night sky. We hope just to be worthy of the opportunity,” Ballard said. “It feels like one of those things that you do not just on behalf of yourself or behalf of your company, but want to do on behalf of humanity."

Icon expects to deliver the structure in a singular lunar day, the equivalent of about 14 Earth days. On Earth, Icon typically builds structures in about one day.

“We'll need a lot of coffee and won't really stop working for 14 days straight once it lands on the lunar surface,” Ballard said. “I mean every single minute and second will count to keep progress."

Austin startup Icon plans development of 3D-printed homes in area

'Hardest construction project in the history of humanity'

Ballard said Icon will use lessons learned from its projects on Earth, as well as three previous space-focused projects, including work with NASA. But the latest project will present a number of new challenges. For example, getting a printer to the moon means limited power and size, while still needing to build structures the same size as on Earth.

"We have every confidence that it will work," Ballard said. "But I think it'll be the hardest construction project in the history of humanity by an order of magnitude."

Icon has been part of several space-related projects for NASA and the Department of Defense. Through a subcontract, the company built a 3D-printed structure at NASA's Johnson Space Center in Houston for a series of missions designed to simulate what life could be like for astronauts living on Mars. The first crew of astronauts is expected to move in soon and crews will stay for one-year stints designed to mimic living conditions on the red planet.

For Icon's new moon project, remote control and communication will be key, Ballard said. There will be a mission control system, and Icon will be able to monitor, support and update the robotic systems from back on Earth, but Ballard said this also means lessons in “aggressive autonomy.”

“We've been doing the same thing in our terrestrial bases and trying to eliminate on-site labor and support to make housing more affordable on Earth, but those lessons, now five years in the making, pretty immediately translate to how to construct on another world.”

As part of the mission, Icon plans to work with lunar samples brought back from Apollo missions and various simulants to determine mechanical behavior in simulated moon gravity. But depending on where the spacecraft lands, the material could be slightly different.

“The geology is different on the east side and also on the west side of Austin. Similar things like that can happen on the moon with different materials and minerals, and elements that can melt at different points, whether they are recrystallized or not, in different ways and at different temperatures," Ballard said. "There will be a lot of research over the next few years to get ready. We will be almost building a recipe book.”

Other work prior to launch will aim to make the system as flexible as possible, with multiple power systems, different speeds, rechargeable batteries and ways to make adjustments after it lands.

"The airplane ticket to get up there is pretty expensive," Ballard said. "You don't really get a do-over. You really have to nail it on the first go."

Fire engulfs facility for Icon, an Austin 3D-printing company known for NASA projects

'A pretty cool way to work'

Meanwhile on Earth, Icon continues with its other projects, including buiding a 100-home community in Georgetown. Icon says it is the first large-scale, 3D-printed housing development in the country. Icon has also been scaling up and now has almost 500 employees.

"Depending on the day, we're working on shelter for the homeless here in Austin or thinking about the moon base," Ballard said. "It's a pretty cool place and a pretty cool way to work."

The NASA announcement follows a fire at Icon's headquarters on Friday. Firefighters responded to the fire at the Yard, a mixed-use development on East St. Elmo Road in South Austin, where Icon had an office and printing facility. The company said there were no injuries, and that it did not expect a meaningful impact to ongoing business actiities

In a tweet, Ballard shared pictures of the fire and said that no one was at the facility at the time, and the printers were all in the field.

“Black Friday. Grateful no one was hurt. Thankfully the printer fleet is out in the field doing good work and teams were at home for the holiday. It’s time to build. We ride,” the tweet said.

This article originally appeared on Austin American-Statesman: NASA picks Austin company to build 3D-printed structures on the moon