NASA Tests 3D-Printed Rocket Nozzle for Future Missions to Moon, Mars

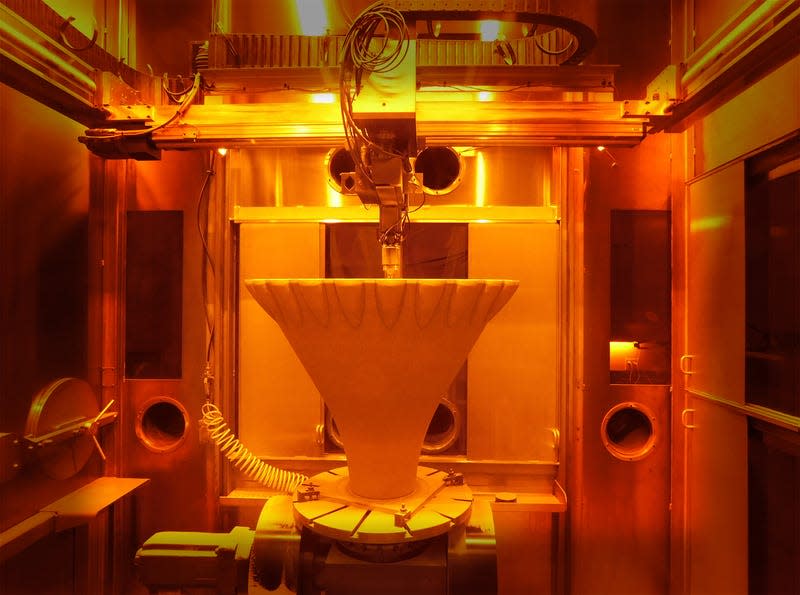

The RAMFIRE nozzle performs a hot fire test at Marshall’s East test area stand 115.

In order to be able to carry heavier payloads through deep space, NASA designed a lightweight rocket engine nozzle made of aluminum that can still withstand the heat of launches.

NASA recently tested two 3D printed nozzles at the Marshall Space Flight Center in Huntsville, Alabama, proving that they can operate in the most demanding deep space environments, the space agency announced. Under a partnership with Elementum 3D, the NASA-funded Reactive Additive Manufacturing for the Fourth Industrial Revolution, or RAMFIRE, project focuses on advancing lightweight, additively manufactured aluminum rocket nozzles.

Read more

Peter Parker Can’t Do The ‘Wakanda Forever’ Salute In Spider-Man 2

Turo Wants Customer To Pay $35,000 After Vandals Smash His Rented Car’s Windows

5 Disappointing Things About Konami’s Metal Gear Solid 'Master Collection'

Watch This Massive Tow Truck Roll Three Times After Hitting Suspected Distracted Driver

RAMFIRE set out to create a weldable type of aluminum that is heat resistant enough for use on rocket engines. The RAMFIRE nozzles are designed with small internal channels that keep them cool enough to prevent melting.

The ability to manufacture lightweight rocket components capable of withstanding high structural loads would allow NASA to send more cargo to deep space destinations. “Mass is critical for NASA’s future deep space missions,” John Vickers, principal technologist for NASA’s Space Technology Mission Directorate, said in a statement. “Projects like this mature additive manufacturing along with advanced materials, and will help evolve new propulsion systems, in-space manufacturing, and infrastructure needed for NASA’s ambitious missions to the Moon, Mars, and beyond.”

The laser powder directed energy deposition (LP-DED) process manufacturing the nozzle at the RPM Innovation (RPMI) facility in Rapid City, South Dakota.

The RAMFIRE nozzle is also built as a single piece using advanced 3D printing methods, requiring far fewer bonds and significantly reducing manufacturing time, according to NASA. Regular manufacturing, on the other hand, may require as many as a thousand individually joined parts. “We’ve reduced the steps involved in the manufacturing process, allowing us to make large-scale engine components as a single build in a matter of days,” Gradl said.

The RAMFIRE aluminum material and additive manufacturing process was also used to construct other rocket components such as a 36-inch diameter aerospike nozzle with complex integral coolant channels and a vacuum-jacketed tank for cryogenic fluid applications.

For more spaceflight in your life, follow us on X (formerly Twitter) and bookmark Gizmodo’s dedicated Spaceflight page.

More from Gizmodo

Paramount delays the next Mission: Impossible, which is no longer called Dead Reckoning: Part Two

Final Fantasy VII Rebirth Devs Have A Big Surprise Planned For Its Most Iconic Scene

It Looks Like The Next Gen Dodge Charger Will Get A Gas Engine After All

Sign up for Gizmodo's Newsletter. For the latest news, Facebook, Twitter and Instagram.