OKC, have a million drinks on Simple Modern, thanks to what CEO Mike Beckham sees in China

Mike Beckham had no intention of just watching the parade of U.S.-based manufacturers, freshly distrustful of the global supply chain, as they headed back home from China rather than keep dealing with disruptions from the COVID-19 pandemic and the Russia-Ukraine war.

He's in the parade himself, with Simple Modern, the company he co-founded and leads, based in Moore. It's about ready to start making its drinkware — insulated tumblers, cups and bottles — as well as bags, backpacks and other consumer products, in a big factory warehouse in south Oklahoma City.

Beckham saw the turn homeward quicker than some.

Business Insider reports that an "overwhelming majority" of American manufacturers are "reshoring" — the reverse of "offshoring" — or plan to in the next three years. By then, Beckham said, the 175,000-square-foot place he's leasing at 4600 SE 59 might be too snug of a fit.

More:Sex, drugs and even a dead body: Nightmarish real estate horror stories in Oklahoma City

After the "proof of concept phase," he said, Simple Modern, with licensing agreements for college and pro sports logos, plus Disney, Nickelodeon, Star Wars and other collections, could "outgrow this place fairly quickly" and require a million square feet of space. It has retail agreements with Amazon, Target, Kroger, Sam’s Club, and Walmart.

Millions are on his mind. He says the company, which he started in 2016 as an importer selling solely through Amazon, plans to make a million "units of drinkware" out of stainless-steel and Tritan plastic, purchased domestically from Eastman Chemical Co., a spinoff from Eastman Kodak, in its first year of manufacturing here.

Simple Modern competes with YETI, Beast and other popular vacuum-insulated drinkware brands. By bringing manufacturing onshore — no more paying the cost of shipping plastic pellets to China and shipping back manufactured products — Beckham said the company "will be better positioned to serve (its) retail partners and maintain affordable prices for customers."

The company employs between 70 and 80 people now, at the factory and headquarters in Moore, and will have 100-plus employees next year, he said.

Simple Modern started in e-commerce, not the physical retail market

Simple Modern, which Beckham, 42, owns with 15 other shareholders, has come a long way from its strictly e-commerce start with $200,000 of his own money. Also in its first year of domestic manufacturing, he said, the "bootstrap company" will invest between $4 million and $5 million on the plant, buying equipment — and doing good.

"We exist to give generously," the company says online.

Simple Modern says it gives away 10% of its profits annually. It's donated more than $1 million worth of water bottles to frontline workers, and has supported more than 1,000 organizations, according to Beckham.

“Our goal at Simple Modern is to make the best products we can while also making a positive, redemptive impact in the world,” said Beckham, whose early career was with Cru, a nonprofit college ministry where he learned to give by being a recipient of others' generosity.

More:3 shopping centers served Oklahoma for 250 years combined. Why they're still in business today

“Despite the challenges that will surely come along the way, the decision to manufacture some of our products domestically is a milestone endeavor for Simple Modern and represents our company’s innovative spirit, growth mindset and commitment to the Oklahoma City community,” he said.

The milestone is one he could hardly avoid.

"There is a major storm brewing in the supply chain. It could dramatically impact everyone's life next year, but almost no one knows about it yet. We are talking empty shelves, crazy inflation, etc.," he said to start a Twitter thread last Sept. 29 that got him interviewed for a story in the Wall Street Journal.

The global supply chain and a tweet heard 'round the world

Beckham tweeted on to explain what he was learning from his contacts in China.

"As a communist country, China is centrally planned. That means that things like electricity usage are planned in Beijing by party officials instead of governed by the supply and demand of the market," Beckham wrote. "At the beginning of the year, China set electricity quotas for each province.

"As a result of supply chain disruptions from COVID and unprecedented factory demand, many of the provinces have used way more electricity than planned. Now, China doesn't have enough coal power."

He posted a map with some dire details surrounding electricity caps and production cuts, and then tweeted this:

"In stainless steel drinkware, 93% of the world's production happens in one province in China. Of that production, about half happens from now until Chinese New Year (Feb. 1, 2022). What that means is that almost 20% of the world's production isn't going to get built this year!"

He went on: "The problem with COVID is that it has led to cascading failures throughout the supply chain. If production drops so dramatically over the coming months then empty shelves will be commonplace. We are talking about a situation where many product types will be completely nuked."

Simple Modern’s decision to shift some production to the United States will let it sidestep the stressed-out global supply chain, material shortages, "chaos at the ports" and other disruptions, Beckham said.

“Domestic manufacturing will not only reduce production delays and surging shipping rates for our company, but it will also help curb the effects of inflation and allow us to continue offering our customers high-quality, premium products at an affordable price,” Beckham said.

What Simple Modern will make at its factory in Oklahoma City

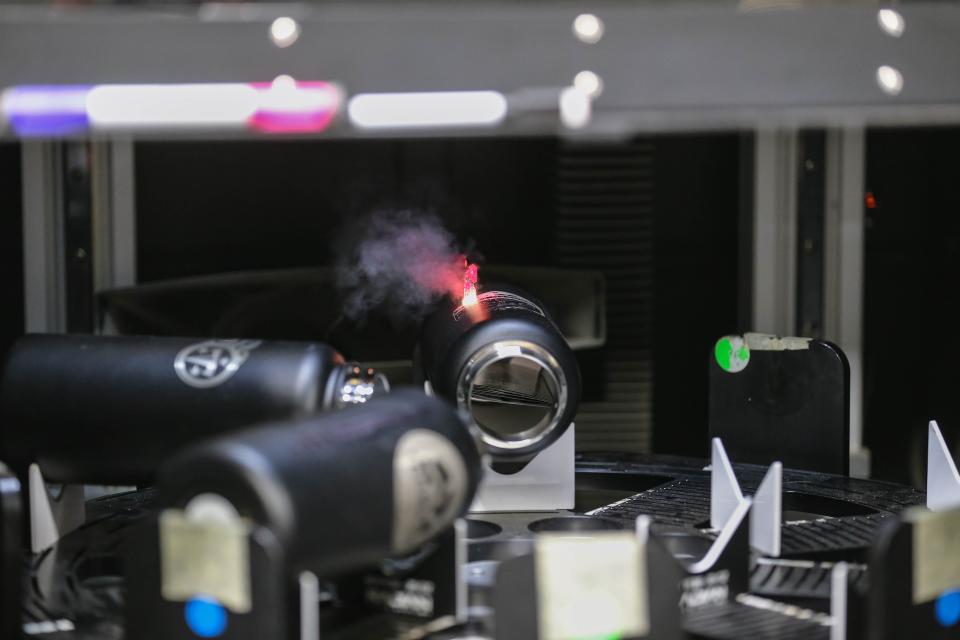

Simple Modern will start this fall with one production line with a blow-molding machine to make 128-ounce, 64-ounce, and 48-ounce Tritan Summit water bottles, said production manager Wes Zimmerman. A second machine for a second line is on order, he said.

"We anticipate adding up to three blow-molding lines making various sized Summits, ranging from 12-ounce to 128-ounce. We are also looking at two injection molding lines to produce various products, some of which are still in development," he said.The first line can produce around 5,000 units per day in a single shift, said Zimmerman, who previously worked in gypsum mining in Norman and Cyril, and paperboard manufacturing in Lawton.

Beaches of Edmond? Check out this future neighborhood, inspired by Florida resort towns

Zimmerman's connection to Simple Modern came through Lee Graves, chief manufacturing and logistics officer, from when they both worked for Harrison Gypsum in Norman.

"Lee contacted me early this year when Simple Modern was ready to begin their adventure into domestic manufacturing and wanted me to be a part of this amazing team," Zimmerman said. "After seeing what Simple Modern was all about and the bright future that lies ahead, I couldn’t say no."

Most of his career has been in gypsum. Now, he's all about tumblers, cups and bottles.

"Based on full-scale models, we anticipate producing 2-3 million domestically manufactured units next year," he said.

Senior Business Writer Richard Mize has covered housing, construction, commercial real estate, and related topics for the newspaper and Oklahoman.com since 1999. Contact him at rmize@oklahoman.com.

This article originally appeared on Oklahoman: Simple Modern tumblers, bottles, cups to be made in Oklahoma not China