ORNL researchers target better, cheaper batteries

Electric battery researchers funded by the U.S. Department of Energy are charged with taking battery technology and the materials used to the next level. That’s one advance needed to help in minimizing climate-altering carbon emissions from American energy sources for the electric grid and transportation vehicles as fossil fuels are gradually replaced by renewable energy.

The goals for future lithium-ion batteries include higher energy content, longer energy storage life, faster charging, affordability, near-zero risk of catching fire, use of clean energy to manufacture and recharge them, use of less toxic and more abundant materials available in the U.S. and reuse of these materials through recycling of spent batteries to stem the depletion of natural resources.

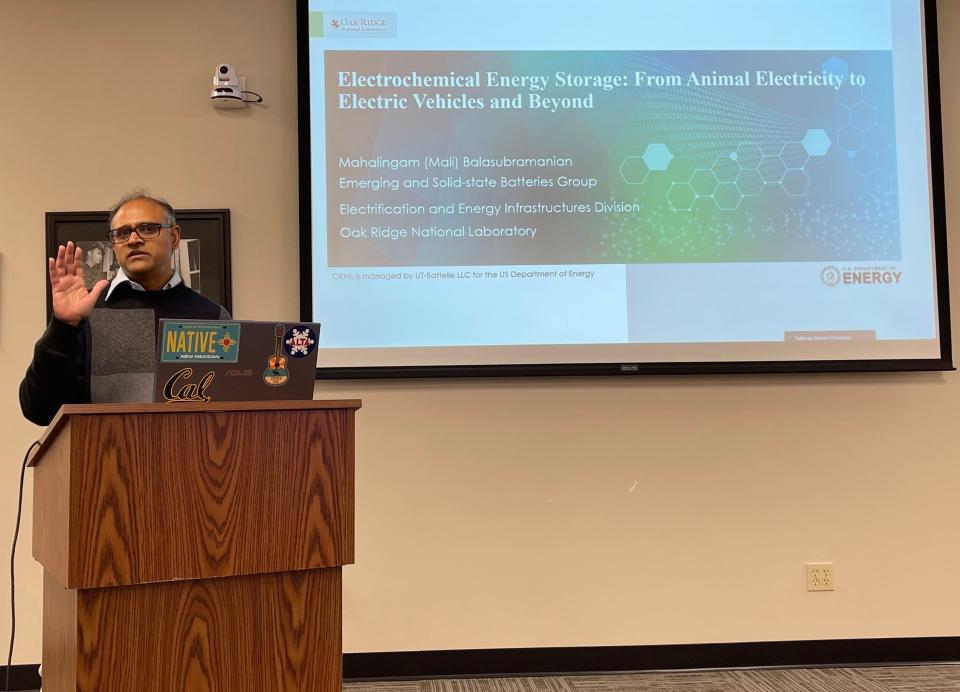

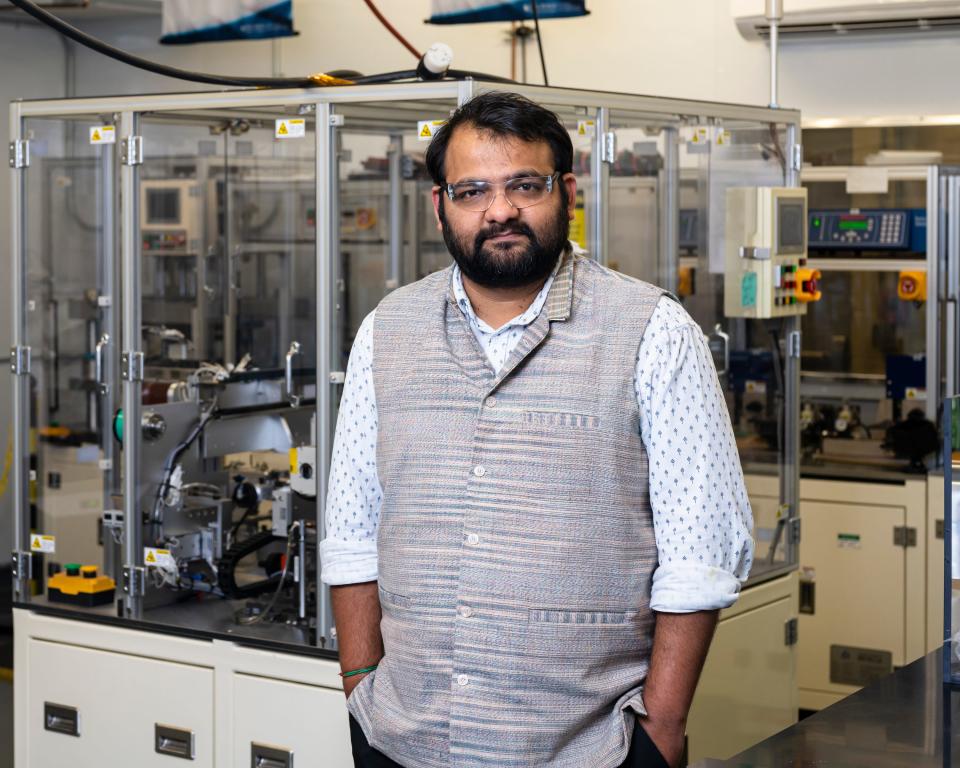

That was the message from Mahalingam "Mali" Balasubramanian, leader of the Emerging and Solid-state Batteries Group in the Electrification and Energy Infrastructure Division at Oak Ridge National Laboratory. He spoke recently to Friends of ORNL about ongoing research at ORNL and other DOE labs to develop many different battery technologies, including advanced solid-state batteries.

Two of his group’s recent innovations have received R&D 100 Awards, often referred to as the "Oscars of Innovation." One ORNL invention has been licensed to a startup battery company in Indiana. Research in his group - described in published papers - has been featured on the covers of two premier scientific journals.

Lithium-ion batteries used in today’s electric and hybrid cars, digital cameras, smartphones, smart tablets and computer laptops have a liquid electrolyte that has a higher risk of bursting into flames than does a solid electrolyte in solid-state batteries.

Balasubramanian noted that the lithium-ion battery was commercialized by Sony in 1991 using pioneering research contributions recognized by the 2019 Nobel Prize in Chemistry awarded to John B. Goodenough, M. Stanley Whittingham and Akira Yoshino.

“A lot of the work on oxide systems used in lithium-ion battery research is funded by DOE,” he stated. He added that the invention of a unique solid electrolyte in the 1990s at ORNL advanced thin-film, solid-state battery technology.

An electrolyte is a substance sandwiched between the battery’s cathode and anode terminals; its primary function is to repeatedly shuttle ions carrying an electric charge between the two terminals within the battery. When a rechargeable battery is connected to an external circuit, it can deliver or receive energy.

“The charging process entails movement of electrons from the cathode to the anode, while the discharging process involves the opposite movement of electrons from anode to the cathode,” Balasubramanian said. “The electron movement in the external circuit is paralleled by concurrent movement of ions in the electrolyte inside the battery.

“The charging process converts external energy to chemical energy in the battery, which can then be converted back to electricity and used to perform work during discharge. After charging, if the battery is disconnected from the external circuit, energy can be stored in the battery for future use as needed.”

Many lithium-ion batteries today have a lithium cobalt oxide cathode and a carbon (graphite) anode. Cobalt is a critical element not abundant in the United States. For that reason, he said, DOE is funding research at ORNL and elsewhere on the use of other metals for cathodes that are “earth-abundant,” such as manganese and iron.

To increase adoption of electric vehicles (EVs) for transportation, he noted, DOE’s targets for batteries include a cost of less than $80 per kilowatt hour (versus $153 today), an EV range of 300 miles and a charge time of less than 15 minutes (because refilling traditional vehicles gas stations takes only 5-10 minutes).

Bigger and more affordable batteries that offer long duration electrical storage will be needed to stabilize the electric grid as it becomes increasingly connected to renewable energy sources such as wind turbines, rooftop solar panels and solar farms. During intermittent downtimes when the sun doesn’t shine and the wind doesn’t blow, batteries charged by the excess power from renewable sources must keep grid electricity flowing.

“The penetration of renewable energy into the U.S. electric grid has reached about 20 to 30%,” Balasubramanian said. “If the penetration of renewable energy into the U.S. electric grid reaches 80%, 10 to 100 hours of storage will be needed for several consecutive days of cloudy or calm weather for our country’s national security and economic well-being. The initial challenge is to find ways to keep the capital cost of long duration batteries that provide at least 10 hours of energy storage as low as $40 per kilowatt hour – half that of the current DOE cost target for EV battery packs.”

Balasubramanian’s group “aims at enabling disruptive, transformative changes,” he said. One emerging application could be batteries to power aircraft for passenger flights. For electrified airplanes envisioned for the next decade, batteries must have an energy density of 800 watt-hours per kilogram, about three times the energy density of today’s best batteries.

In 2022, a low-cost, high-speed electron beam technology developed for processing lithium-ion battery electrodes won an R&D 100 award for ORNL’s Zhijia Du, Chris Janke, Jianlin Li and David Wood.

"It can replace processes using expensive organic solvents that can be carcinogenic,” Balasubramanian said.

The technology, which also received an award for excellence in technology transfer from the Federal Laboratory Consortium, was licensed in 2021 to Ateios Systems, an Indiana-based startup.

Another R&D Award winner in 2022 was the Solid-State Battery Performance Analyzer and Calculator (SolidPAC) developed by ORNL’s Marm Dixit and Anand Parejiya. This interactive tool helps users design a solid-state battery for a desired application, Balasubramanian said, noting that it guides researchers in “figuring out what materials and design criteria are needed to increase battery energy density. It has been well received by the solid-state battery community.”

At the DOE-funded Battery Manufacturing Facility on ORNL’s Hardin Valley campus in Knox County, staff produce pouch batteries that “allow translation of knowledge and technical know-how from the lab scale to the industrial scale,” Balasubramanian said. Other ORNL researchers devised several novel processes for manufacturing battery materials that he described.

One hydrothermal process uses heated water to synthesize a cobalt-free cathode material consisting of lithium, nitrogen, manganese, aluminum and oxygen. Another one creates uniform, crystalline cathode particles by combining sodium, nickel, manganese and oxygen. A third process makes use of hot isostatic pressing for the large-scale production of solid-electrolyte materials that have the most promising properties.

Charging and discharging solid-state batteries can stimulate the growth of thread-like dendrites in lithium in the solid electrolyte, potentially triggering undesired internal short circuits and unwanted energy releases, Balasubramanian said. ORNL researchers have found a way to pass a low current to prompt electrochemical healing, halting dendrite growth.

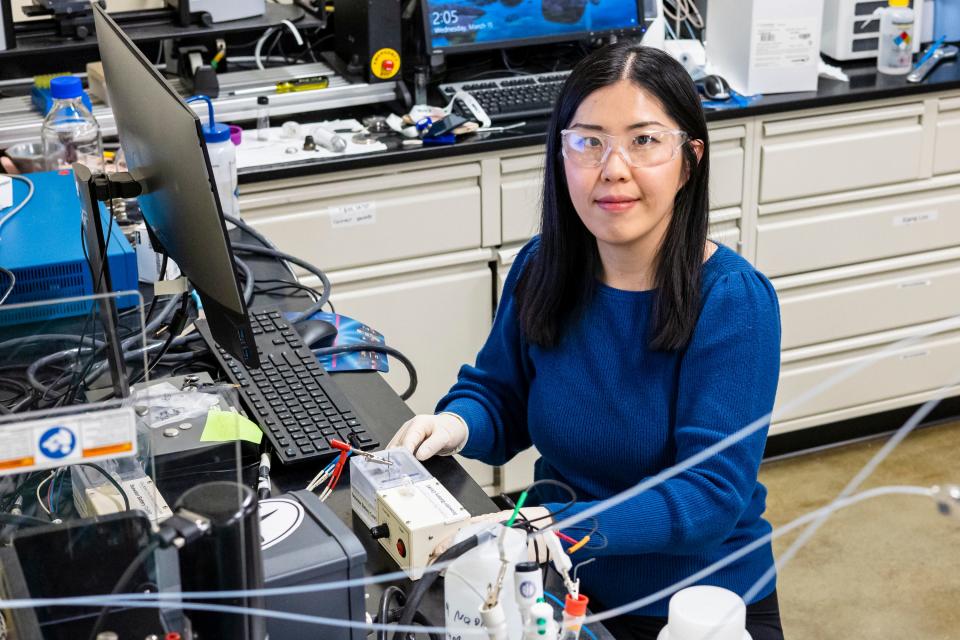

Mengya Li has been improving “seawater batteries,” a relatively cheap battery that is a promising candidate for long duration energy storage. The battery has two chambers, with seawater in one and a liquid organic electrolyte in the other. These chambers are separated by a solid electrolyte made of sodium, zirconium, silicon, phosphorus and oxygen. By introducing a tiny amount of titanium oxide, she boosted the electrolyte’s stability and ionic conductivity.

Zhija Du and other ORNL researchers have shown that the speed of charging lithium-ion batteries can be ramped up if the batteries have high-performance electrolytes.

To slow the depletion of critical materials in the earth’s crust, researchers have conducted considerable research on recycling lithium-ion batteries for ReCell Center, a collaboration of four DOE national labs, including ORNL, and four universities.

ORNL’s Yaocai Bai has developed water-based direct recycling to recover the unused pristine material in anode scraps discarded in electrode production, as well as a method to remanufacture battery anodes from the scraps. He was also involved along with researcher Lu Yu in devising an experimental process that uses citric acid to recover cobalt and lithium from spent cathode materials.

Balasubramanian also mentioned the Earth-abundant Cathode Active Materials Consortium, which is led by Argonne National Laboratory, where he performed research previously. Consortium goals include designing a sustainable, fully earth-abundant, high-performing lithium-rich material, as well as a model cathode system consisting of compounds of lithium manganese oxide and lithium iron oxide. Balasubramanian, along with ORNL researcher C.Y. Kwok, performs advanced characterization projects for the consortium.

Balasubramanian, who was born and raised in India, leads a group of researchers from many countries. He described his staff as highly talented and “diverse with backgrounds ranging from chemistry to material science, mechanical engineering, electrical engineering and physics.”

This article originally appeared on Oakridger: ORNL researchers target better, cheaper batteries