From parts to hypersonics, Pentagon sees 3D printing as ‘game changer’

WASHINGTON — The growth of additive manufacturing is a “game changer” for the military — one that can facilitate everything from rapid repairs to aircraft after bird strikes to accelerating the development of hypersonic weapons, a top Defense Department official said Wednesday.

Keith DeVries, deputy director of the Office of the Secretary of Defense’s Manufacturing Technology Program, said in a Defense News webcast Wednesday that additive manufacturing has made “tremendous leaps” in the last few years and opened up novel possibilities for creating new weapons and components.

Additive manufacturing has particularly come in handy when designing new systems, DeVries said, allowing programs to iterate during the rapid prototyping process much more quickly than in traditional manufacturing processes.

It has also been used to create “one-off” spare parts to repair aircraft or other systems that might otherwise have to wait long periods for a replacement component to work its way through a slow supply chain, he said.

“We’ve even seen bird strikes repaired on aircraft overnight, or in a few days, through additive manufacturing,” DeVries added.

3D printers can also quickly create new tools, which typically take a long time to arrive when they are made in traditional ways, he said.

And DeVries said the scale of objects that can be 3D printed is also increasing, to the point where entire structures such as houses can be built that way.

The Defense Department has taken notice of those advancements, he said, and is looking for ways to apply them.

“In the defense side … having the ability to print a runway or a hangar or something literally overnight can be amazing,” DeVries said.

Additive manufacturing has advanced since its early days, when it made objects from more fragile polymers to materials with higher tensile strength. Today, DeVries said, these manufacturing techniques create objects from high-entropy metals that are particularly strong and stand up to wear and tear, using lasers to melt metals that can withstand high temperatures and allowing more complex shapes to be crafted.

“Those advancements have been fundamental unto themselves,” DeVries said. “Now, it feels like we’re turning a corner and we’re trying to find what the sweet spot is for how big of a build volume is appropriate for us to apply that technology.”

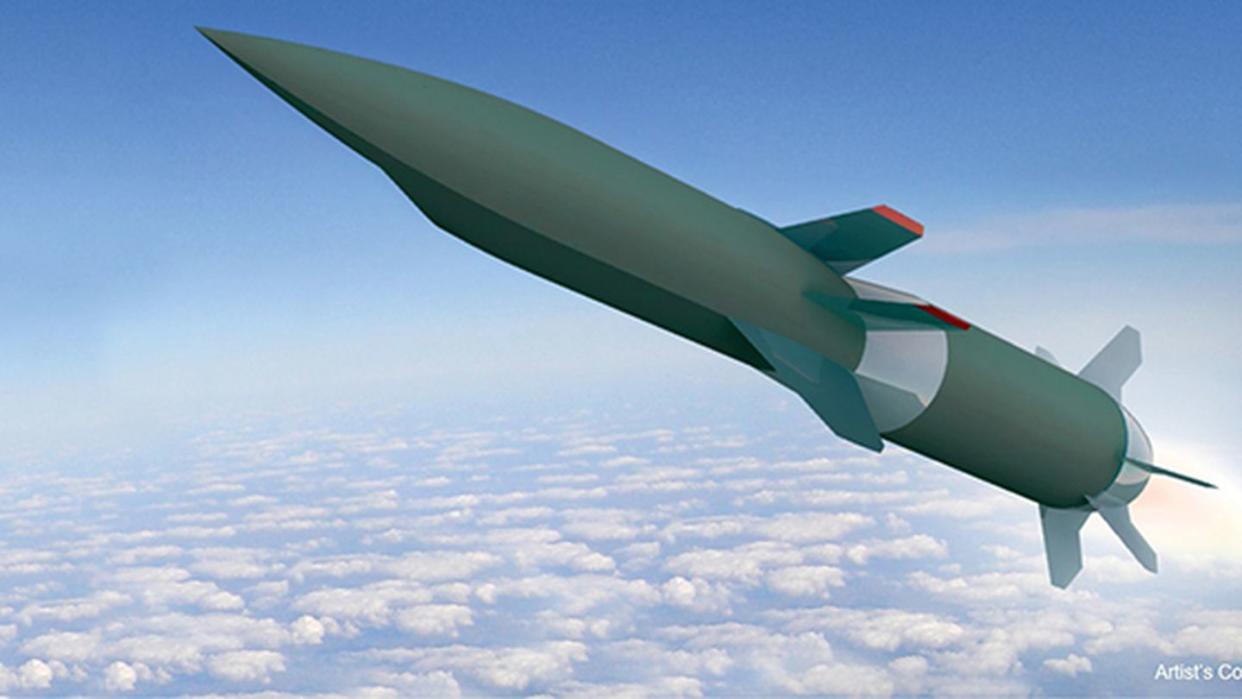

And hypersonic weapons are a prominent example of a program where additive manufacturing can be useful.

Scramjet propulsion systems that are central to some hypersonics, for example, require complex chambers that can be difficult to make, DeVries said. But 3D printing these components is allowing hypersonic weapons manufacturers “some fantastic capabilities,” he said.

Additive manufacturing would allow scramjet components to be made from high-temperature metals in a way that eliminates the need to have complex welds or brazing joints, DeVries said. Those joints need to be tested to ensure they’re sound, he said, but a component made via additive manufacturing that doesn’t have those joints won’t need such testing.

“Being able to incorporate additive manufacturing is enabling us to manufacture complexity that has not been able under the subtractive, traditional manufacturing methods,” DeVries said. He noted hypersonic development is still in the rapid prototyping phase.

But DeVries said traditional manufacturing techniques such as casting and forging still have a place, and warned the DoD and manufacturers should only seek to replace those techniques with additive manufacturing “in a very intentional and frankly limited way.”

“We want to treat [additive manufacturing] as a tool in the toolkit, and we want to apply it exactly where it’s necessary, and where it adds the most value,” DeVries said.