Pendleton's 1895 Woolen Mill Still Makes The Brand's Famous Blankets

If there's one thing every home needs, it's an investment piece. Whether it's a KitchenAid or a vintage table, the staple should be timeless and last long enough to gain heirloom status. Those familiar with Pendleton's beloved wool blankets know what makes them worth the splurge. They're soft, durable, and classic enough to inspire entire rooms. For over 100 years, Pendleton has been making the must-haves for designers and vintage-hunters alike.

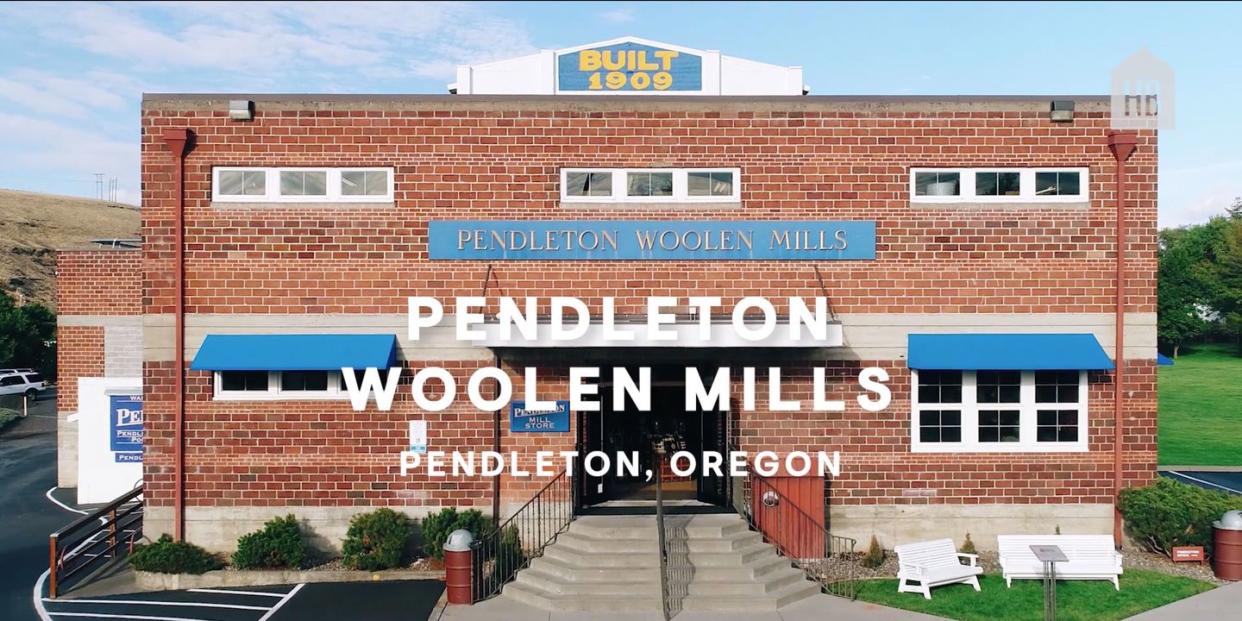

Pendleton Woolen Mills owes its name to the Oregon town that held its first factory, built in 1895. Unlike other centennial businesses, the blanket fabricator—which now also offers apparel, rugs, and tabletop accessories—has kept its headquarters in its Oregon home, choosing to stay family-owned and operated long after its successes made it a household name. The company's longevity is largely thanks to its roster of local wool shepherds, some of whom have been suppling the company for generations.

The Krebs family has been providing wool for Pendleton for over 90 years. Their sheep moving process, documented for Pendleton's Youtube channel, takes their herds to places like the National Forest for stronger coats and better nutrition. "You can buy cheaper wool shirts, but you're not going buy a wool shirt that will last you 20 years," said Chad Kreb, retired Principal Operator of the family farm in an interview with Pendleton.

Once the wool is harvested and delivered to the woolen mills, workers clean it and turn it into fleece by a process called scouring, working the individual fibers into thread spools. Pendleton spins nearly 2 million pounds of yarn a year to create some its most iconic patterns. This is to give them a variety of colors in the dyeing process and the ability to weave hundreds of variations on 10 of its original Jacquard patterns.

This dyeing process—along with wool's unique properties—is what makes these blankets family heirlooms. "Wool as a fiber itself has so many unique and positive attributes to it. It insulates against moisture, cold, and heat...its structure allows the dye to penetrate deeply into the core of the fiber. This creates a permanent and deeply rich color," says Amanda Coppa, Pendleton's senior merchandise manager.

The dyed spools are then individually thread into eye of the heddle to form a warp in the mechanical looms, which are each capable of 4,000 separate yarns per warp. The looms create yards of mesmerizing fabric which are then cut, finished, and inspected. "Every square-inch is inspected by hand," says Coppa.

The brand started as a fabricator for trading posts, designing alongside Native American tribes to make ceremonial pieces, now still given in celebration of important milestones, like graduating school or the birth of a child. Pendleton has continued in that tradition offering blankets and merchandise designed by and benefiting Native Americans, including its series for the American Indian College Fund.

Some of the company's most loved pieces have been in collaboration with nonprofit organizations and charities like the National Park Foundation, the Fisher House Foundation for veterans, and NARA's work with American Indian women. The Glacier National Park blanket, with it's four-colored stripes, remains a best-seller and a collector's item for antique-hunters with an eye for original labels going back to early 1900s.

With a process as time-tested and rigorous as Pendleton's it only makes sense that these blankets last as long as the mill itself.

Follow House Beautiful on Instagram.

You Might Also Like