Planned Oak Ridge lab facility to meet growing U.S. demand for medical radioisotopes

Some people joke that you can’t trust atoms “because they make up everything.” Truth is, lots of doctors and cancer patients have learned to trust certain radioactive atoms because they effectively treat a potentially fatal disease, often by killing cancerous tumor cells.

They are called radioisotopes. A radioisotope is an unstable form of a chemical element that releases radiation as it breaks down and becomes more stable. Some radioisotopes are used to power NASA spacecraft. Others are employed to nondestructively detect early defects that need repair to help ensure the safe operation of aircraft, bridges and dams, for example.

Unfortunately for the United States, some 100 useful radioisotopes are not made in America. Most come from Russia, and others are shipped here from Australia, Europe and South Africa.

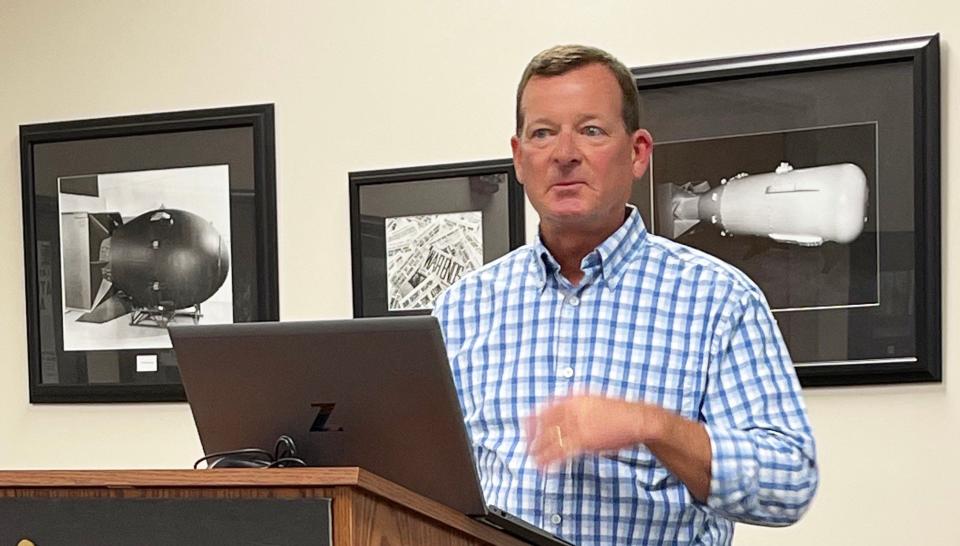

The U.S. Department of Energy’s goal is to reduce the nation's dependence on foreign isotope suppliers, said Robert F. "Rob" Peacher, a nuclear operations expert with Strata-G LLC, and a part-time consultant to an Oak Ridge National Laboratory directorate, in his recent talk to Friends of ORNL.

The good news, he added, is that DOE’s Office of Science is funding the design and future construction of a Radioisotope Processing Facility at ORNL. The RPF is designed to help meet the growing U.S. demand for high-priority radioisotopes. The RPF is planned to be open by 2032. It will be the first new non-reactor nuclear facility to be built at ORNL since the 1960s by Office of Science of DOE, and its predecessor, the Atomic Energy Commission.

Mike Farrar of ORNL is the project director for the RPF. Radioisotope processing consists of chemical, thermal or physical actions taken to separate, isolate or refine radioactive isotopes or to enrich an element in one specific radioisotope.

ORNL’s non-reactor nuclear facilities house the remote handling of nuclear materials such as radioisotopes and nuclear fuels, said Peacher, who conceived and developed the design for the highly flexible RPF. He added that an environmental assessment will be presented to the public later this summer, and next year modular hot cells will be procured and site preparation for the facility will likely begin.

The High Flux Isotope Reactor, the only reactor operating at ORNL, is the western world’s sole supplier of californium-252, an isotope used for well-logging, industrial scanning and starting up nuclear reactors. Cf-252 was used to treat cancer and for detecting explosives, but was later replaced by actinium-227 (an effective prostate cancer treatment) and nickel-63 (explosive detection), both currently made at HFIR.

By irradiating neptunium oxide with neutrons, since 2015 HFIR has been adding to U.S supplies of plutonium-238 needed to power future deep NASA space missions. Pu-238 from HFIR is powering the Perseverance rover now exploring Mars.

To meet the rising demands of U.S. research institutions and government agencies for made-in-America radioisotopes to fulfill domestic medical, industrial, research and national security needs, Peacher said, ORNL has been given a leading role.

The strategy, he said, will be to boost the current processing capacity to fully utilize the HFIR’s capability of irradiating additional target material and to use ORNL’s available expertise and processes once RPF is in operation. The lab has radioisotope, radiochemistry, nuclear facility operations, transportation and rad waste expertise and processes in place.

“ORNL has checked all the boxes,” Peacher said, adding that the RPF will provide processing capabilities currently lacking for targets irradiated at HFIR. He noted that plans to replace the pressure vessel and beryllium neutron reflector in ORNL’s 58-year-old reactor “should extend HFIR’s life significantly.”

Peacher mentioned that the first radioisotope shipment of carbon-14 produced at ORNL for medical purposes was given in 1946 at the Graphite Reactor by research director and future Nobelist Eugene Wigner to the director of the St. Louis cancer hospital. Over the next five years, the lab made more than 20,000 shipments of radioisotopes to medical and research facilities, according to the ORNL website. Later, the government turned over radioisotope production to the commercial sector. Its production of radioisotopes declined as its reactors were shut down.

In the 1960s, ORNL had 13 reactors and at least 10 nuclear facilities, Peacher said. Now, he said, the lab has only one reactor, HFIR, and five nuclear facilities, including the Radiochemical Engineering Development Center, which will be supplemented and not replaced by the new RPF.

In addition to RPF, what will help make ORNL the largest domestic producer of stable isotopes and radioisotopes in the 2030s will be the U.S. Stable Isotope Production and Research Center (SIPRC), now being built on the main lab campus using DOE funding. It will expand the nation’s capability to enrich stable isotopes for medical, industrial, research and national security uses – a capability Oak Ridge had from 1945 through 1998 using the calutrons at the Y-12 National Security Complex. SIPRC will use advanced electromagnetic separations and gas centrifuge equipment, Peacher said, adding that some of the enriched stable isotopes will likely be irradiated in HFIR to make radioisotopes.

RFR to process 9 needed mission isotopes

RPF will process nine needed mission isotopes that will be produced at HFIR, he said. They are:

Thorium-229, for targeted alpha therapy for cancer (parent of actinium-225 and bismuth-213);

Iridium-192, for industrial radiography and medical applications;

Actinium-227, for targeted alpha therapy for cancer (parent of radium-223 and thorium-227);

Gadolinium-153, for bone density measurements;

Strontium-90, for radioisotope power sources for spacecraft and for cancer therapy (parent of yttrium-90);

Phosphorus-33, for medical and biological research;

Promethium-147 (first discovered at ORNL), for radioisotope power sources and industry measurements;

Carbon-14, for medical, biological and agricultural science research;

And a yet-to-be-determined radiopharmaceutical cancer treatment processed to the Food and Drug Administration’s (FDA) current Good Manufacturing Practices (cGMP).

“These nine high-priority radioisotopes require added processing capabilities that RPF can provide to meet mission needs for flexibility,” Peacher said.

The RPF, which will have two floors, will have a footprint of about 52,000 square feet. Instead of the traditional stationary hot cells heavily shielded by concrete walls, the modern facility will have eight modular hot cell bays, each with the capacity to house a series of three to five modular hot cells, referred to as three-packs, four-packs, and five-packs. They can be assembled offsite or onsite, and they are portable, versatile and well-shielded with steel or lead on all sides.

They each will have a pair of telemanipulators for remote work in a high-radiation environment, a large lead glass window, an attached glovebox, highly configurable options, a rear shielded access door, rapid transfer ports and large interior space. Systems for fire protection and for the transfer of a cask of a HFIR product from a truck to a modular hot cell will be installed in the RPF.

“The building will have three-packs, four-packs, and five-packs of modular hot cells on the first floor and utilities and support spaces on the second floor,” Peacher said, joking that he will not provide the project team with six-packs until after the facility is completed and online. The RPF will have a control room, change rooms, conference space, analytical lab for quality assurance and movable walls. It is expected that RPF will have about 100 staff members.

Peacher said it will be a “juggling act” to figure out how many additional radioisotopes can be worked on at the same time (sometimes using hazardous chemicals) and what the annual production can be at the RPF within the extensive DOE nuclear safety requirements.

Because many of the nine radioisotopes will be used for therapeutic drugs, the facility will have clean room environments that meet current Good Manufacturing Practice regulations established by the U.S. Food and Drug Administration for production of medical isotopes for human use, Peacher said. The stringent cGMP regulatory standard is intended to ensure high pharmaceutical quality and no contamination because consumers expect that the medicines they take are safe, effective and trustworthy.

This article originally appeared on Oakridger: ORNL facility to meet growing U.S. demand for medical radioisotopes