The Pungent History of America's Garbage Mountains

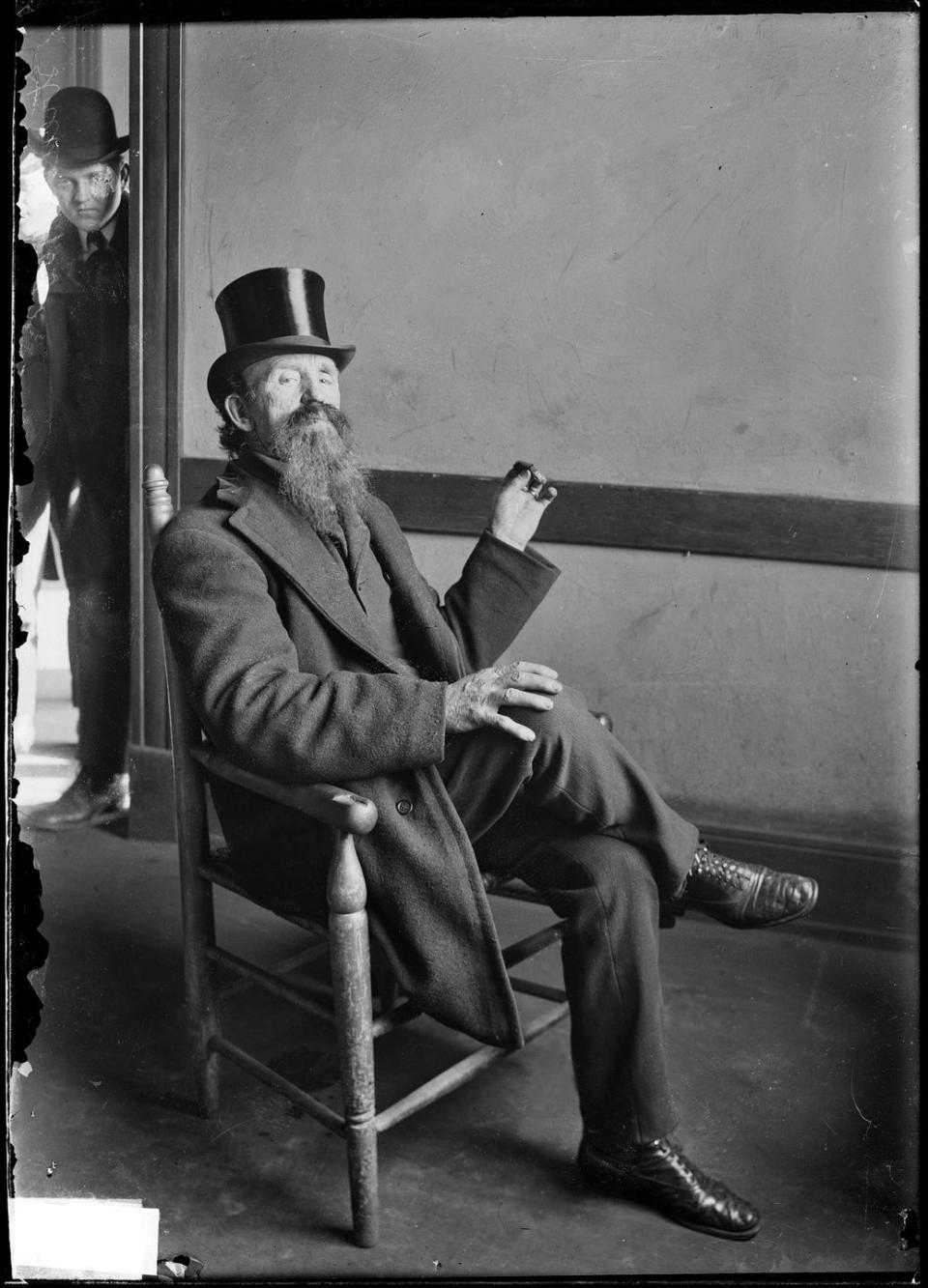

It took 50 shots for the Chicago Police Department to arrest George Wellington Streeter. The date was November 14, 1915, and “Cap” Streeter had been ruling over his proclaimed “District of Lake Michigan,” an ad-hoc settlement just off the shore of said lake, for 40 years. The raid marked the end of the decades-long Streeterville saga, a land dispute that saw Streeter—a former deckhand, miner, and Union soldier—attempt to literally build his own country on top of a trash pile about 150 yards off Chicago’s shoreline. The absurd notion of a nation built on trash carries the overtones of an ironic art installment, but in the annals of garbage-related engineering, the District of Lake Michigan was more prescient than not. Streeter was a trash king, and considering where American redevelopment efforts are going, he was ahead of his time.

As the story goes, Streeter was a ferryman on Lake Michigan when a storm beached his craft on an offshore sandbar in July 1886. Waves deposited sand around the boat, and Streeter surmised that he could live rent-free on his accidental island if enough material accrued.

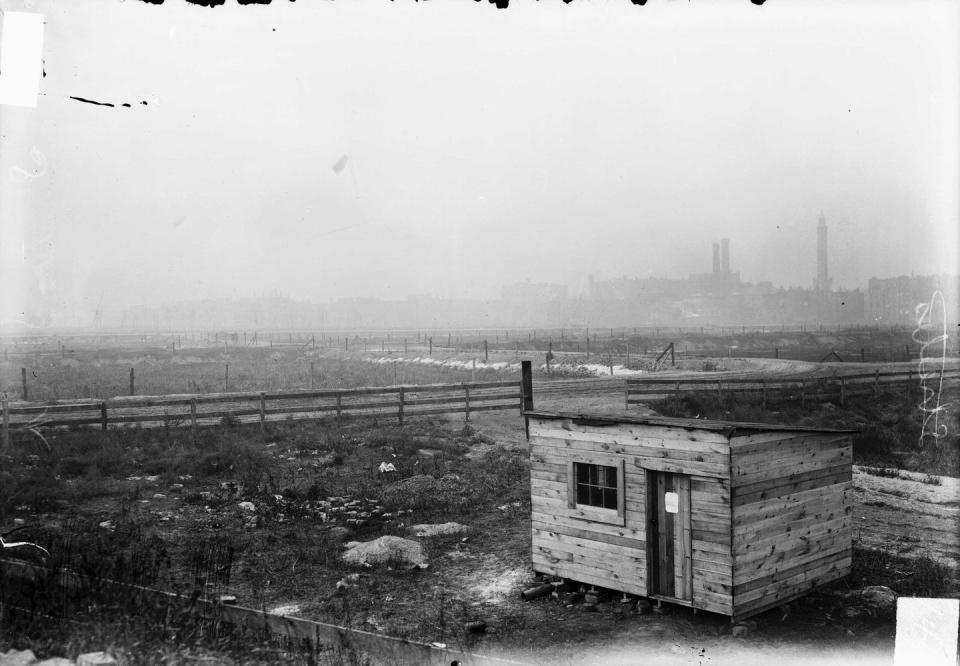

It was common in the 19th century for people to throw their garbage in swamps, in the ocean, or in “dumps,” which were then little more than unregulated holes in the ground (Sanitary landfills wouldn’t appear until the 1970s and the introduction of federal and state guidelines for waste management.) The lack of oversight in Streeter’s day allowed him to pay waste companies to dump trash into Lake Michigan around his sandbar, swelling his plot. His domain grew to an astonishing 186 acres, and Streeter turned a tidy profit collecting rent and selling titles on his tract, which he dubbed “the District of Lake Michigan.” To protect his claim from the city of Chicago, he used outdated maps showing that the district was beyond city jurisdiction; he also employed ethically dubious surveyors to rule that he was within his legal rights to run his garbage empire independent of Chicago. “When I came here, there wasn’t a particle of land for me to squat on,” Streeter argued.

Streeter’s occupation sparked more than mere technical disputes, however. In 1899, authorities reportedly demolished Streeter’s original boat residence and everything else in the District of Lake Michigan. “One shingle was not allowed to rest upon another,” reads a contemporaneous account. But Streeter just relocated and rebuilt until he eventually died of pneumonia in 1921. His surviving family members sued the city for control of the District of Lake Michigan, but Chicago won in court in 1928, and the Streeter case was closed.

Chicago incorporated the District of Lake Michigan into the city’s growing Lake Shore Drive development, and by the 1920s the shoreline appeared much the way it is today. Landmarks such as the Museum of Contemporary Art, the Wrigley Building, the Chicago Tribune Tower, various Northwestern University buildings, and the Magnificent Mile were all built on Streeter’s turn-of-the-century garbage. Part of this area is still known as Streeterville in honor of its unique beginnings.

Why We Build On Trash

Today, landfills are canvases for city planners around the world. Transportation centers, stadiums, and even entire neighborhoods—such as Chicago’s Soldier Field, New York’s Battery Park City, and San Francisco’s Oracle Park—are built on landfills. Building atop garbage helps us manage waste, develop otherwise unusable land, and mitigate some of the environmental concerns that come with other forms of new development. Some developers are optimistic that reusing landfills could present a workable option for low-cost housing, or accommodate large-scale population movement due to climate change. Cap Streeter’s lake territory might have been controversial in its day and exaggerated by legend—there isn’t even a record of the storm that wrecked his boat—but Streeterville’s demonstrable value persists for the landfill developers of today.

“Landfill redevelopment projects tend to be real estate projects, and you know what matters in real estate: location, location, location,” says Mike McLaughlin of SCS Engineers in California, who specializes in brownfields and landfill redevelopment. “A landfill in an urban area might be the only piece of open land in that area. People go to extraordinary lengths to redevelop because the property is so valuable.”

In areas where land is at a premium, closed landfills offer abundant acreage for new development. Not only is the land likely cheaper because it’s complicated by the presence of the accumulated waste, but developers can often use grant funding to remediate and build on formerly contaminated sites, explains Sara Ramsden, an environmental engineer with Minneapolis-based Barr Engineering.

But building on a landfill involves more than just plopping a building atop it like a seashell on a sandcastle. Ramsden explains that redevelopment should account for the unique challenges posed by the waste, including contamination, gas generation, and unfavorable geotechnical conditions. Some landfills are pockmarked with dormant sinkholes waiting to pull buildings into their subterranean filth. As such, most landfills since the 1980s are carefully engineered projects, designed to blend into their surroundings once they’re closed.

Anatomy of a Landfill

The modern sanitary landfill emerged in the 1970s, when states first devised legal guidelines for massive waste management. Prior to these regulations, America was dumping its waste just about wherever it wanted—even in Lake Michigan. But then the rise of plastics and industrial waste changed the composition of dumps, convincing regulators and engineers to institute more careful policies. Today’s landfill has become so sophisticated that it can be considered an engineering marvel even before it’s redeveloped, an often-overlooked mode of infrastructure designed to contain contaminants and “spatially liberate” neighboring communities.

The typical foundation of a modern landfill site begins with a few feet of low-permeable clay covered by a plastic liner, then a few feet of sand. Around and within the foundation, drainage systems collect and pump away leachate—the toxic slurry that accumulates as rainwater seeps through the trash—toward wells at the base of the landfill. The wells collect the leachate for treatment and disposal. Meanwhile, venting systems collect and expel gas produced by the decay of the garbage.

Atop the foundation is the waste, but only a small section of each landfill, called the working face, is open for dumping at a time. Heavy compactors outfitted with spiked treads crush and aerate the day’s waste to encourage decomposition, and then bulldozers and backhoes cover the open areas with dirt to control odor, animals, and dust.

When a landfill reaches capacity, it’s “capped” with another layer of low-permeability clay and another low-permeability plastic membrane. A layer of soil several feet thick goes on top of the liner, then topsoil, then grasses and other short-rooted vegetation. Landfill operators monitor and caretake the sites for 30 years or more after closure; any leakage or breach is remediated as needed.

Settlement presents a significant risk and introduces an element of uncertainty. A typical landfill could settle 5 to 20 percent in the 30 years after it’s capped—between 6 and 24 inches a year. This sinkage can burst pipes, crack foundations, and destroy roads, so engineers study the composition of potential landfill development sites to assess future stability and to develop designs that can account for settlement. “Sinkage depends on the composition of the waste and how long it’s been there,” Ramsden says.

Given the 30-year waiting period, landfills that were closed in the 1960s, ’70s, and ’80s are now prime for redevelopment if their challenges and conditions are properly understood. At some sites, most settling and outgassing has already taken place; these sites are more manageable. To put any final touches on a landfill before redevelopment, crews might relocate waste to make stability more uniform, though this can be costly. They might also tamp down the landfill through “deep dynamic compaction,” a process in which large cranes drop weights of several tons over the site.

How to Build On a Landfill

Building atop a former landfill typically requires extra structural support. “The opening expectation is that any building, any parking ramp, any significant piped utility, is going to have to rely on a deep foundation,” says Barr Engineering’s Dan Fetter, an expert in environmental site assessments. To stabilize such a foundation, construction crews drive steel pilings through the garbage and into the underlying soil, topping these with a structural slab so that the buildings and structures are not relying on support from the settling landfill materials. The pilings have to penetrate deep enough into suitable soil or bedrock to provide an ample foundation. McLaughlin says some landfill redevelopment projects near Atlanta have pilings of 65 feet, while similar projects in San Francisco have 130-foot pilings.

Differential sinkage is a constant concern for developers. This is when some parts of a project sink while others don’t, due to differences in underlying support. In this scenario, developers might use what McLaughlin describes as “grade beam transitions” to solve the problem.

These transitions feature a “hinge slab” between the stable parts of the project and the sinking parts. Say a building, secure on its pilings, sits adjacent to a sinking parking lot. The hinge slab pivots on the building side so that as the refuse settles, the grade beam sinks too, though without causing structural damage. When the beam settles too far—typically just over 2 degrees, McLaughlin says—crews excavate the parking lot and jack the hinge slab back up to the proper slope.

Redevelopment at landfills can also be, quite literally, explosive. As the organic material in a landfill decays and bacteria break down the trash, methane gas can build up, creating an extreme explosion hazard if the gas were to migrate into buildings. To help collect and safely vent the gas away from buildings, subsurface gas conveyance piping is embedded in layers of sand and gravel beneath and above the waste, while monitoring points across the landfill site help keep an eye on methane levels. Sub-slab venting and sub-slab depressurization systems installed at the redevelopment buildings can also help contain and remove harmful vapors, Ramsden says.

Landfill gas is the third-largest source of human-related methane emissions in the U.S., according to the EPA, equivalent to the output from 21.6 million cars on the road for a year. Some landfills have onsite infrastructure to harness this gas and turn it into a usable energy source. The EPA’s Landfill Methane Outreach Program and Landfill Gas Energy Project Database lists more than 500 landfill energy sites across the country, with applications such as “generating electricity, firing kilns, upgrading [landfill gas] into pipeline-quality gas, heating greenhouses and buildings and providing steam for industrial processes.”

Rumpke Waste and Recycling Services, headquartered in Ohio, currently has four onsite landfill-gas-to-energy facilities at its landfills in Ohio and Kentucky, which convert methane to liquefied natural gas. These systems collect gas through a series of collection wells buried within each landfill. As the gas is pulled from the decomposing trash, it’s directed to the recovery plants for further processing to be converted into pipeline-quality energy. According to Rumpke, the company’s flagship site outside Cincinnati produces enough BTUs of gas to power 30,000 homes and businesses annually, while their smaller sites produce natural gas or electricity for roughly 2,500 or more homes each year.

“We were among the first back in 1986 when we started doing it here at our Cincinnati landfill,” says Amanda Pratt, Rumpke’s communications director. “But today, [recovering landfill gas] is becoming a more common practice. It’s a great way to make a renewable energy source from the garbage, and it helps with conditions and odors at landfills.”

The Future of American Trash

Developments built on landfills are not fail-safe—erosion often exposes layers of buried garbage in areas that were built before today’s environmental regulations—but when done correctly, building on landfills is more desirable environmentally than developing an otherwise untouched greenfield.

“Most landfills have good access roads and other infrastructure nearby,” McLaughlin says, unlike new land that requires extending infrastructure to meet it. “As suburban and urban land uses have moved away from city centers, landfills are often the only remaining large land parcels suitable for development. Instead of sprawling into new areas, these land uses can be developed atop landfills—the sort of ‘infill’ development that most consider smart growth.” That’s development that takes advantage of existing infrastructure, such as highways, to construct new land uses near population centers.

There are also redevelopment opportunities in cities like Detroit or Cleveland, which may have thousands of vacant residential and industrial properties. Cleaning up these sites can be a complicated process for developers, given the potential presence of hazardous building materials used in old sites or residues from industrial processes that may have leached into the ground. But if the properties are in “opportunity corridors,” cleanups might be worth it. This is the term used by Terry Schwarz, director of Kent State University’s Cleveland Urban Design Collaborative, for sections of a city that are located between thriving business or residential areas. In these neighborhoods, remediating larger parcels of land can link rejuvenated sections of the city back together, creating new residential and professional hubs.

“The question of what to do with land reclamation is central to the redevelopment of older industrial cities,” says Schwarz. That’s especially relevant for cities like Cleveland that have been steadily losing population.

Landfill development science will continue to evolve. McLaughlin points out that lightweight geofoam is now being used as a substitute for soil when covering landfills, which creates a lighter load on top that will minimize settlement. Building techniques such as controlled modulus columns, which are cement columns set in a grid pattern to reinforce soft ground, and spread footings, which have wider feet to distribute the weight of the structure more evenly, will maximize the stability of structures built on landfills even further.

“It is likely that engineers of the future will have more options to address settlement and stability—[such as] automatic leveling devices powered by alternative energy sources that maintain the structure to close tolerances,” McLaughlin says. “We are limited only by our imagination and the laws of physics.”

However, as with any kind of development, there are non-engineering considerations that come with building on landfills. Redeveloping landfills as shopping centers, office parks, and golf courses can lead to gentrification, says Ignacio Dayrit, director of programs with the nonprofit Center for Creative Land Recycling. This might displace people who put up with the hazards of living near a landfill in the first place. While it is rare for housing to be built on landfills, there are some subsidies for developing housing on sites that have other environmental concerns, Dayrit says. Subsidies are typically limited for retail spaces or other businesses, he adds, limiting reuse benefits to residents living adjacent to landfills.

And while remediating former waste sites might limit development in natural areas, more development always means more consumption and more waste that ends up in a landfill somewhere else. At 27 million tons, plastics accounted for just under 19 percent of new landfill waste in 2018, according to the EPA. Some companies are working to divert plastic from landfills and put it to better use, such as an additive for mortar and asphalt. JD Composites in Nova Scotia builds homes with panels made from laminated polyethylene terephthalate (PET) plastic foam. The panels are lightweight, weather-resistant 6-inch walls with no thermal bridging, and they use approximately 192 plastic bottles per square foot. That means the average house recycles more than a half million bottles, says JD Composites president David Saulnier.

“Building a home is a 30-second solution,” Saulnier says, referencing 2016 research by Euromonitor noting that the world consumes 1 million bottles per minute, with 93 percent ending up in landfills or the environment. But he hopes the reuse of plastic waste in construction will pave the way for a broader culture of industrial recycling and reuse.

Building with old plastics and terraforming mountains of garbage may seem like somewhat of a backward solution, but the best alternative—developing solutions that create less waste in the first place—would involve reworking countless industry practices and changing human consumption habits en masse. So for the short term, former landfills could house less wasteful commercial development, incorporate more reconstituted waste, and take advantage of the natural gases generated by the underground decomposition. These initiatives would dwarf Streeterville, but maybe Cap was onto something.

You Might Also Like