Separation can be good: How success in chemical separations helped make ORNL world class

In the world of human families, “separation” can be a heartbreaking word. But in the world of science and technology, achievements and expertise in separating atoms and molecules from each other have helped make Oak Ridge National Laboratory a world-class scientific institution.

“ORNL has developed landmark separation processes that have truly changed the world,” said ORNL Corporate Fellow Bruce Moyer in a recent talk to Friends of ORNL. “The lab has some awesome accomplishments in separation science and technology.”

These achievements helped the United States win World War II and clean up the hazardous nuclear wastes that resulted from the production of thermonuclear weapons during the Cold War. Moyer led a team that developed separation processes for removing the most radioactive element in one of the most voluminous nuclear wastes so it can be turned into glass to isolate it from the environment at the Savannah River Site in South Carolina. For that work, he and the team received the 2013 Secretary of Energy’s Award from then-U.S. Department of Energy Secretary Ernie Moniz.

Now, ORNL researchers in the Chemical Sciences Division, including Moyer, have been applying their expertise to helping usher in a clean energy future for the U.S.

The lab’s fame originated with its success in separating small amounts of plutonium from irradiated uranium slugs from what was later called the Graphite Reactor, the world’s first continuously operating reactor. When the Los Alamos lab directed by J. Robert Oppenheimer received and analyzed the plutonium in 1944 from Oak Ridge, scientists there realized they had to frantically design and test a new method of making and exploding an atomic bomb fueled by plutonium instead of uranium.

The show-stopping scenes of the new “Oppenheimer” movie re-enacted the successful detonation of the first atomic bomb in July 1945 over the New Mexico desert and the excited reaction of Oppenheimer and his colleagues. The new plutonium-fueled bomb was the predecessor of the second atomic bomb dropped on Japan, which ended the most devastating war in human history.

Thanks to separation techniques used especially at the Graphite Reactor and the High Flux Isotope Reactor, ORNL has a 70-year history of isotope research, development and production, Moyer said. Separating the byproducts of irradiated uranium at ORNL led to the discovery of many new isotopes and the elusive lanthanide element, promethium.

“Through further irradiation of transuranic elements separated at ORNL, superheavy elements such as tennessine, element 117, have been discovered, and more are coming,” Moyer later stated in an email.

“In 1946 the first shipment of a radioisotope to a hospital for cancer research was made from the Graphite Reactor,” Moyer told FORNL. “In the 1960s, more than 10,000 radioisotope shipments were made annually for uses in research, industry and medicine, especially cancer diagnosis and treatment. Today ORNL focuses on producing isotopes not available in the private sector.”

A key to a clean energy future is nuclear power because nuclear plants do not emit greenhouse gases. As uranium becomes more expensive, separation techniques developed at ORNL may be deployed. Moyer said that ORNL has devised methods for recovering uranium from phosphate rock used to make fertilizers, from ore leachates, and from seawater.

More recently, ORNL researchers have been inventing separation processes for removing climate-altering carbon dioxide from the atmosphere and recovering rare earths from ore for use in powerful magnets needed in motors for wind turbines and electric vehicles.

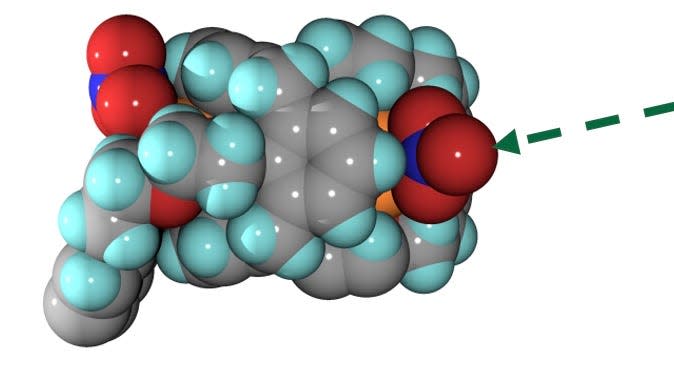

Moyer said that ORNL researchers led by Radu Custelcean “have found that molecules called Bis-IminoGuanidines (BIGs) that grew out of guanidine chemistry work at ORNL binds to carbonate molecules strongly enough to remove carbon dioxide from the atmosphere and crystallize it.”

He added that experiments indicate that solar heating of the filtered crystals could enable capture of the CO2 for sequestration in an underground geologic carbon storage site. This process has been commercialized, and a company is trying to scale it up into an industrial process. In August, DOE announced it will be funding the construction of direct-air capture plants in Louisiana and Texas for removing airborne CO2.

Concerning separation techniques ORNL is developing for DOE’s Critical Materials Institute, Moyer said, “We have emerging ORNL technologies for separation of rare earths and lithium from ores and from recycled end-of-life products.” Lithium is needed for EV and electric utility energy storage batteries.

In answer to a question, Moyer said, “Next to China, the United States is the second largest producer of rare earths in the world. We ship 43,000 metric tons of rare-earth concentrate every year to China because our country doesn’t have a way to do the separation economically.

“But that’s changing. The mining company MP Materials that operates the Mountain Pass Mine in California has been shipping neodymium concentrate to China. Now, it is beginning to separate neodymium and praseodymium from the ore and ship these rare earths for domestic use as ingredients for magnets.”

Savannah River Site

Moyer devoted most of his lecture to the lab’s award-winning process of separating highly radioactive cesium-137 from nuclear waste generated at the Savannah River Site (SRS), where DOE’s Savannah River National Laboratory is located. In the early 1950s, five reactors and supporting facilities were built at SRS to produce tritium and plutonium-239 for the fabrication of thermonuclear weapons. The original separation process for treatment of the waste in dozens of SRS tanks had to be abandoned because of the risk of generating unsafe amounts of flammable benzene that might fracture the concrete tanks.

At the SRS, the pre-treated salt waste exhibiting low radioactivity is blended with cement, slag and fly ash to form “saltstone,” which is immobilized in underground saltstone vaults. ORNL was asked to devise processes to deal with the highly radioactive waste stored in tanks.

Moyer described the fits and starts of 35 years of basic and applied research that led to development and deployment of processes engineered to meet DOE goals for nuclear waste cleanup at SRS. DOE required the removal of 99.9975% of the cesium-137 from 31 million gallons of salt waste (mostly sodium nitrate with traces of radioactive strontium-90 and actinides) in 49 SRS tanks.

“The cesium constitutes about 98% of the radioactivity in the salt waste but less than 0.01% of its mass,” Moyer said. “So, we’re talking about pulling a needle out of a haystack.”

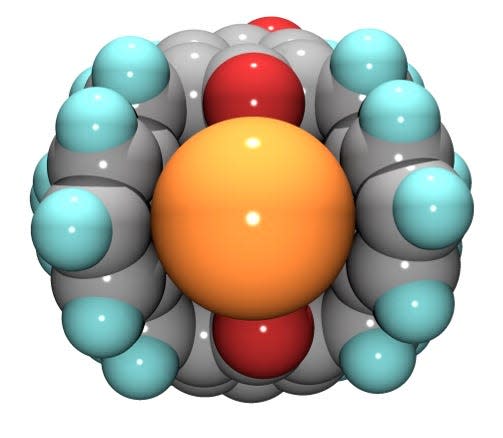

He explained that a ring-like molecule constructed from a crown ether married to a related calixarene macrocycle, called a calix-crown, has an internal space that can attract and hold a smaller charged atom such as cesium. The guest, a positively charged cesium-137 ion, fits nicely in the cavity of the selected host molecule.

While such molecular recognition provides amazing selectivity, he added, fundamental research showed that the co-extraction of nitrate from the waste limits the strength of extraction of the cesium. Nitrate is present in the waste because nitric acid was used to dissolve and recover plutonium and uranium during reprocessing of spent nuclear reactor fuel (using the standard PUREX process first developed at ORNL).

So, Peter Bonnesen on Moyer’s team came up with a fluorinated compound that aids the co-extraction of nitrate, thereby giving their nascent solvent-extraction process the boost it needed to reach DOE’s goal of removing more than 99.9975% of the cesium-137 ions from the salt waste.

Solvent extraction, he explained, is an effective method for separating ions and molecules by mixing an oily liquid like kerosene with the aqueous solution containing the mixture of ions. In the present case, the calix-crown extractant pulls the cesium into the oily liquid away from all other salts in the water solution.

“Our team had lots of help from other national labs and SRS engineers to come up with a working pilot plant by 2008 that treated seven million gallons of waste over 10 years,” Moyer said, adding that his team led the chemical development of the pilot plant’s Caustic-Side Solvent Extraction, or CSSX, process.

“Now SRS has the $2 billion Salt Waste Processing Facility, which started treating the highly radioactive waste in 2022. Next year, this plant will begin using our next-generation process, which is 100 times better.

“The next-generation process will knock years off the waste treatment schedule, as it raises the throughput. It will save billions of dollars because of DOE’s investment of several tens of million dollars in research. That’s a really nice return on investment.”

This article originally appeared on Oakridger: How success in chemical separations helped make ORNL world class