Smithfield wants a cleaner future in Sioux Falls. How its new wastewater facility plays a role.

Most people would grimace at the sight and smell of a concrete basin filled with hog matter ― urine, feces and blood dispersed within millions of gallons of dark chocolate-like water.

Gazing down at one of the 60-by-30 foot tubs at the Smithfield hog plant in Sioux Falls, where the frothy brown liquid churned beneath his feet, Jason Lindquist cracked a smile.

"I couldn't be more proud of this company," Lindquist remarked, the bodily sludge continuing to slosh below him.

Four years into Lindquist's tenure as Smithfield's director of environmental affairs, playing cheerleader for the company's sustainability efforts comes with the title.

Even when it means wrapping a bow around a fecal matter.

Because, to be clear, it's not the sewage within the lagoons that the Smithfield employee was keen on hyping up. It's what those lagoons bring to community the hog house calls home.

Since May, the Virginia-based company has seen a noticeable decrease in their release of nitrates in South Dakota, and it's mostly thanks to a new wastewater treatment facility, a $45 million investment by the meatpacking giant to clean up the sewage the plant directly deposits into the Big Sioux River.

The Argus Leader was offered a first look at the wastewater treatment facility as part of a rare on-site tour, where journalists were able to photograph the array of new, state-of-the-art technology, which promises to reduce the company's wastewater emissions in time with their new permit and the stricter nitrate discharge limits that took effect July 1.

"We could've changed our processes to be in compliance with the new permit," Lindquist told the Argus Leader as part of the tour Wednesday. "We wanted to go beyond compliance."

More: North Dakota court halts WOTUS rule in South Dakota, 23 other states

'We just want to do better for the river.'

Stepping into the newly built facility, Lindquist led two Argus Leader journalists and three other Smithfield staff members into the influent room of the building, where the group was immediately met with the whirring drone of pumps pulling pretreated wastewater through large pipes.

This is where the first stage of treatment begins for the sewage. Here, wastewater is sucked through screens to help separate fine organic matter from the actual liquid. A large flow meter monitors the amount of wastewater that pulses through Smithfield's mechanical digestion system on any given day.

"Usually, we're pumping out around 2.2 million gallons of water a day," Lindquist said.

It's a volume he attributes to "food safety." It takes a lot of water to properly sanitize pigs as they're being processed into a product, he explained.

The large pipes, about a foot in diameter, carry the early-stage sewage up into the ceiling, which is where the real action happens.

On the roof of Smithfield's clean-up building, five large, concrete lagoons run end-to-end, nearly filled to the brim with a fudge-textured sludge. A solid-looking layer of wastewater, textured like over-baked brownies, hovered above the gently churning ooze. On one end of the basin, a constant vacuum point sucks the dark liquid from one lagoon to another.

These basins are part of Smithfield's new denitrification process, which is crucial to reducing the amount of toxic nitrates emitted from the facility.

More: South Dakota has one record of acting on 44-year-old foreign ag land law

Inside the basins, many "bugs," or bacteria, eat away at specific chemicals and compounds in the wastewater. One of the five million-gallon basins, as part of what's called the aerobic stage, first converts ammonia, a byproduct of the pig slaughtering process, into nitrate, a less harmful compound.

"Ammonia is very toxic to aquatic life. Nitrate [is] way, way, way less so," John Meyer, senior director of environmental affairs at Smithfield Foods, told the Argus Leader. "The reason actually that there's a big push in the U.S. to get rid of nitrate is not because it's toxic to aquatic life and fish. It's because it promotes the growth of algae … and when algae grows, it depletes the oxygen for the fish."

From there, a suction pipe slurps the wastewater from one concrete tub to another. In an adjacent basin, a surface aerator oscillates back and forth as the mechanism blends the mixed liquor with force.

It's in this lagoon where Smithfield will see the pay-off in terms of reducing nitrates. By churning the hog waste, oxygen is removed from the mix, Lindquist said. The denitrified contaminant is released directly from the lagoons as nitrogen gas, a much less problematic emission.

"From there, we have another anoxic and aerobic basin, where the wastewater will be recycled through the system, reducing our nitrates even further," Lindquist explained.

As he spoke, stray specks of deoxygenated waste would rarely splash out from the lagoons.

"It's outstanding," he said.

This process, Lindquist promised, will reduce their water-destined nitrate output by two-thirds. As for that remaining one-third, the hog plant has some new purification processes to mitigate their pollution.

The leftover liquids are then funneled through the facility's membrane bioreactor. Despite the techie name, this wing of the facility doesn't offer much to look at walking in the door.

But as the tour group marched over the metal covers that tile this second-to-last stop, the hollow clang of boots on metal reveals there's more to this space.

Underneath the sheets, the remaining wastewater pumps through a final series of pipes, which hold thousands of bundled filtration tubes packed within. Each membrane hole is only about as thick as a human hair, Lindquist demonstrated with one of the tubes. This adds another means to physically separate biologic matter from the wastewater.

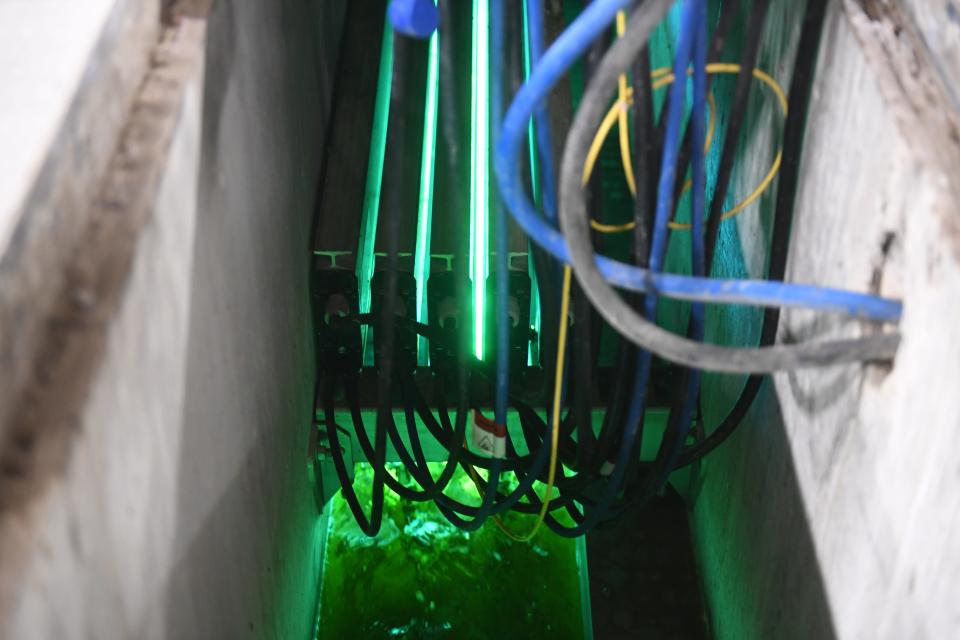

But before the wastewater is sent out the door, it has to travel through one last corridor, where ultraviolet lights hang from above. This final measure destroys any lingering bacteria and pathogens before it can be discharged into the river.

In years prior, Smithfield Foods would bleach its outflow. UV is about as effective, Lindquist said, and better for the environment.

"It's one less chemical we're putting into the water," Lindquist added. "We just want to do better for the river. That's our goal."

Smithfield Foods has to make up for years of pollution in the Big Sioux

The impetus of the upgrade is not entirely based in altruism. Smithfield's Sioux Falls facility, formerly and colloquially known as the old John Morrell plant, has been releasing many millions of pounds of toxic chemicals into Sioux Falls' beloved river for decades.

The company has come under governmental scrutiny along the way, though the penalties assessed have largely been slaps on the wrist to the billion-dollar corporation.

In 2011, Smithfield was fined more than $200,000 for multiple discharge violations, which included the release of three times the limit of ammonia. Another $53,000 fine was levied at the company for a similar issue in 2018. One year later, the pork processor violated permit limits yet again for total suspended solids, biochemical oxygen demand, ammonia, fecal coliform and toxicity tests, totaling more than $45,000 in penalties.

The U.S. Environmental Protection Agency has accounted for other environmental missteps. Between November and December 2020, Smithfield violated its surface water discharge permit for high toxicity concentrations and total suspended solids.

Nitrates, one of Smithfield's largest contaminants by volume, also present a danger for humans as well. Nitrate concentrations in groundwater used for drinking above the EPA's 10 milligrams per liter standard can cause blue-baby syndrome in infants, which starves the victim of oxygen, and lead to health complications in elderly adults.

Sioux Falls sources its drinking water upstream of Smithfield, so the city's drinking water sources never meet with the company's effluent.

Communities downstream of the pork plant, however, could be impacted by point-source pollution.

The South Dakota Department of Agriculture and Natural Resources' Water Quality Monitoring Access Portal tracks nitrate levels at certain numbered monitoring sites along the Big Sioux River. Sites 1 through 10 represent water sampling locations upstream of Sioux Falls, while Sites 11 and onward track water quality south of the city.

Many of the data collection sites north of Sioux Falls are well below the 10 milligram per liter EPA benchmark for nitrate (which DANR measures as nitrogen), ranging from 1.8 to 2.2 milligrams per liter based on a five-year average.

But just past the pipes that dump Smithfield's sewage, those numbers, albeit still within safe parameters, jump. Site 11 ― the sampling site immediately downstream of the plant ― currently averages around 4.5 milligrams per liter. At Site 12, just east and downstream of the City of Sioux Falls Wastewater Treatment Plant, the average increases again to about 7.7 milligrams per liter before dipping back down to about 4.4 milligrams per liter near the Big Sioux Recreation Area.

Nitrate levels are known to fluctuate, according to DANR's website. But based on the department's data, measurements for the nitrogenic material have steadily risen at sites past Smithfield since 2020.

And within that same timeframe, the pork plant's nitrate emissions reached new heights.

An Argus Leader exclusive in April revealed Smithfield's Sioux Falls meatpacking facility was one of the worst water polluters in the U.S., based on the latest EPA data available at the time. Just as well, Smithfield's direct releases of nitrates, a toxic compound, reached all-time-highs in 2020 and 2021.

In terms of volume, the story hasn't changed much in recent years. Smithfield has since reported its 2022 releases to the EPA, and the agency's Toxic Release Inventory data shows the company output 4.95 million pounds of nitrates last year ― only 2021 was higher at 5.1 million pounds, and 2020 was nearly par at 4.93 million pounds.

There's a good reason for this, Meyer maintained. Improvements in Smithfield's ammonia-to-nitrate conversion system, Meyer said, led to their unprecedented nitrate effluent. In other words, their treatment systems have been so effective at scrubbing out the truly terrible ammonia that they've been emitting more of the less-than-deadly nitrate than usual.

"We improved the aeration system … to get better nitrification and now we've got a really good denitrification system to fully get rid of the nitrate," Meyer said. "That's why the nitrate went up, and now the nitrate is getting gone."

Starting on July 1, 2020, the day their new Surface Water Discharge permit took effect, Smithfield Foods had three years to comply with updated restrictions on their releases that would take effect on July 1 this year ― the company had zero restrictions on nitrate pollution until a little more than a month ago.

Going forward, Smithfield's Sioux Falls plant is limited in how much nitrate it can release into the Big Sioux River on a monthly and daily basis. Their current permit allows the plant to shed an average of 50 milligrams per liter of nitrate each month. The facility also cannot exceed a daily maximum of 88 milligrams per liter of nitrate in a single day.

Since 2020, years before the updated permit would enforce these new standards, Smithfield's nitrate emissions well exceeded the then-looming thresholds, according to EPA's Enforcement and Compliance History Online data. Between February and December 2021, Smithfield's 30-day average nitrate emissions ranged between upward of 240 milligrams per liter ― only in March 2021 did the company barely dip below 200 milligrams per liter in that same timeframe.

After an outlying dip in January 2022, Smithfield's nitrate emissions once again continued to double and almost triple its nitrate releases from February 2022 to March 2023, with monthly averages ranging from 157 to 229 milligrams per liter of nitrate.

Though not nearly as high, the meatpacker's nitrate output was still at least double the deadline amounts in every month of 2020 ― all legal and otherwise ordained by DANR until July 1.

After years of unabated nitrate discharges, Smithfield Foods looks to do right by Sioux Falls

It wouldn't be until April that the meatpackers emissions would show any signs of slowing down.

After starting construction on their promising facility in May 2021, Smithfield Foods' was finally able to flip the switch on their new wastewater treatment system in May of this year.

Already, the meatpacker has seen success in this regard. The plant's monthly average nitrate emissions saw deep ― though still insufficient ― cuts, dropping from the 200-range to 60 milligrams per liter in May and about 76 in June.

Their daily maximum nitrate offloads slimmed, as well, to 98 milligrams per liter in May, just over the benchmark of 88. They jumped their daily limit to 162 milligrams per liter one month later.

For Smithfield's engineers, those two months served as a dress rehearsal for the real performance: the July measurements.

"The new limit for nitrate became effective on July 1. So, that's the one that matters. That's when we we really dialed our system in, and it's been running fantastically since then," Meyer said.

While the facility's nitrate discharge amounts have yet to be uploaded to EPA's ECHO dataset, Smithfield provided Argus Leader with their reported data.

For the month of July, Smithfield Foods' monthly average nitrate emissions measured 36 milligrams per liter, below their new limit. They've also halved their daily maximum, with only 44 milligrams per liter reached on any given day.

Smithfield's proof is in the pudding

Downstairs from the bioreactor and on the last leg of the tour, Lindquist raced ahead of the group to where the outflow pipes reside. Next to a small concrete wall sat a beaker, which the excited environmental rep grabbed on his way to a nearby spigot.

Filling the glass about three-fourths of the way full with wastewater, he'd let the pipes make Smithfield's case.

Holding the beaker aloft, a clear, yellow-tinged liquid gently sloshed within. To the naked eye, no sooty particulate or bacon bits could be seen ― only bubbles.

Turbidity meters attached to the outflow pipes provide a more accurate assessment of the sewage. One reads 0.159 nephelometric turbidity units (NTU), which is the measurement of sediments within a liquid. 1 NTU is the EPA standard for drinking water.

This earns a humble brag from the Smithfield folks on the tour: That's cleaner than the city of Aberdeen's drinking water, one employee remarked.

But after all is said and done, whether you can drink Smithfield's water straight remains an unknown.

"Back in the day, we used to have CEOs come down and drink the [processed] water. It made for a good photo-op," Lindquist said. "But I'm not going to do that."

Dominik Dausch is the agriculture and environment reporter for the Argus Leader and editor of Farm Forum. Follow him on Twitter and Facebook @DomDNP and send news tips to ddausch@gannett.com.

This article originally appeared on Sioux Falls Argus Leader: See inside Smithfield's new wastewater facility in Sioux Falls