Steve VanderVeen: The story of Holland Sugar Company

Before Kollen Park Drive, there was Holland Sugar Company. And before there was a sugar beet industry, there were forests.

In 1839, potato grower Lucius Lyon introduced Michigan’s Saginaw Valley to the sugar beet. But the industry didn't initially take root. In 1884, Joseph Seemann, a Saginaw printer, brought seeds back with him after visiting Germany.

More History: Charles McLean was 'in the middle' of everything

More History: George Hummer and the creation of West Michigan Furniture

More History: Arend Visscher and James Huntley lived on a hill

He sent them to a partner, who forwarded them to Dr. Robert Kedzie, a chemist at Michigan Agricultural College (now Michigan State University). Kedzie imported 1,500 pounds of seeds from France and gave them to local farmers, while boiler manufacturer Harry Wickes, Thomas Harvey and grain merchant George Morley raised money for beet-growing tests.

The result was a process for growing beets and extracting sugar, and the discovery that three years of raising beets meant 100 years of raising trees.

To support the fledging sugar beet processing industry, the Michigan Legislature passed a bill in 1897 that paid sugar beet processors one cent per pound for the sugar they produced — IF they paid Michigan farmers at least $4 per ton for beets that contained at least 12 percent sugar.

That year, Bay City became home to the Pioneer Sugar Company. In 1899, Holland locals Charles McLean, George Hummer, Arend Visscher, Isaac Cappon, John C. Post, Albert LaHuis, Christian Den Herder, Cornelius De Roo, Heber Walsh and others founded the Holland Sugar Company.

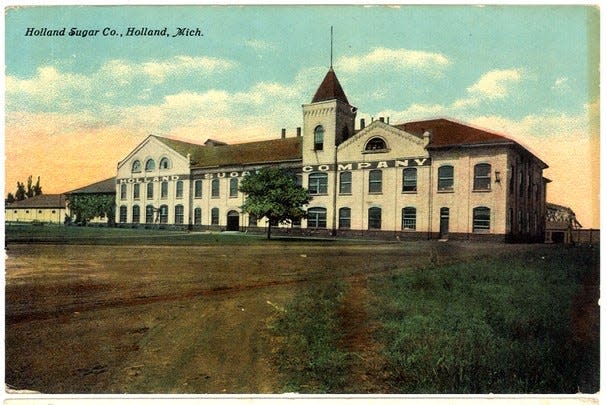

McLean served as manager. The plant, located between 14th Street and 15th Street, just west of Harrison Avenue, consisted of a boiler house, a pump, a lime kiln, a warehouse, a machine shop and two football-field sized beet sheds.

Douwe Yntema, a professor at Hope College and, later, Gerrit J. Van Zoeren, worked there as chemists.

The company’s first year was a success. Local farmers allocated over 1,500 acres to growing sugar beets, and the plant produced 2.4 million pounds of sugar, earning the state’s bonus. The company then paid a seven percent dividend to shareholders.

The next year, the Michigan Supreme Court ruled that the state’s bonus plan was unconstitutional. Still, in subsequent years, farmers contributed between 22,000 to 30,000 tons of beets grown on 4,000 to 21,000 acres of land, and the plant produced between five and nine million pounds of sugar.

Subscribe: Learn more about our latest subscription offers!

As a result, shareholders received dividends ranging from four to 10 percent, and farmers received about $6 per ton ($210 per ton in today’s dollars).

In 1911, the Holland Sugar Company acquired the St. Louis, Michigan, Sugar Company. Charles McLean’s sons Charles and Sears joined the business. In 1912, the Holland-St. Louis Sugar Company built an additional plant in Decatur, Indiana.

The rumblings of World War I sent sugar prices higher. But once the war started, the federal government no longer allowed imported seeds from Germany, Holland Sugar’s supplier. The war also brought a labor shortage and price controls.

After the war, Sears McLean, now Holland Sugar’s superintendent, traveled to San Antonio to meet with labor agencies and recruit migrant workers to help farmers weed the fields and harvest the beets.

In 1923, three train cars — one hundred workers — arrived. In 1926, 15 buses carrying 500 workers arrived. That year, the board of the Holland Sugar Company accepted a buy-out offer from the Continental Sugar Company of Toledo, Ohio. Not long after, the plant in Holland closed.

However, under the leadership of William and John Vandenberg, it reopened in 1933 —in the middle of the Great Depression — as the Lake Shore Sugar Company. To support their effort, the Holland City Council passed a resolution asking the people of Holland to use Holland beet sugar as opposed to Cuban cane sugar. It seemed to work.

In 1935, farmers allocated 5,200 acres to beets and the plant processed 19,000 tons of beets. In 1936, it processed 28,000 tons of beets.

Then, in 1940, rumblings of World War II sent sugar prices higher. However, with the threat of fuel rationing, migrant laborers stayed home for fear they might be stuck in Holland for the winter.

Fortunately for Lake Shore Sugar, local women filled the labor gap, and the plant processed 60,000 tons of beets yielding 15 million pounds of sugar. But in 1942, the Doughnut Corporation of America, a chain operator of donut shops, purchased Lakeshore Sugar and other sugar processing companies and, in 1943, closed the local plant.

Information for this article comes from Robert Swierenga’s "Holland, Michigan," michigansugar.com, The Holland Sentinel and restaurant-ingthroughhistory.com.

— Steve VanderVeen writes about local business history. For a limited time, see his upcoming books at kickstarter.com/projects/holland-me/holland-and-me-the-series.

This article originally appeared on The Holland Sentinel: Holland History: The story of Holland Sugar Company