In Sweetwater, a century of the 'Golden Ticket' is celebrated at USG

SWEETWATER – This was no pyramid scheme. In fact, it was a town and one backed by a company that would become an integral part of Nolan County for the next 100 years.

Pyramid was the name of a small community started outside the then-new United States Gypsum plant in 1923. At the time, Sweetwater was suffering from a housing shortage with some new plant workers having to live in Fisher County and commute to work.

While that might not seem like much today, in 1923 that was a little more problematic. That required owning an automobile and, of course, driving roads that weren’t nearly as well-maintained as they are now.

So an engineer in charge of the new plant took it upon himself to design a small town outside the plant, laying out plats, naming streets and putting the lots in the resulting blocks. As the homes went up with the factory, workers began to move in and stayed until the housing crisis in town resolved itself.

Why call it Pyramid? Supposedly in honor of the pyramids of Egypt which were said to be plastered with gypsum on the inside.

The history of the company town, told in the form of a 23-year-old article from the Sweetwater Reporter, was on display Tuesday as the company celebrated its first century in Nolan County. Company leaders and local dignitaries gave presentations and conducted tours of the facility which makes over 30 different types of their Sheetrock brand product.

“Of any company, this was the first plant in Texas to make wallboard,” said David Sanchez, the plant manager. “Originally it was just a packing department and one board line, now we have three board lines and our quarry keeps growing as we mine different areas.”

USG mines the gypsum on-site, and an upcoming $60 million state-of-the-art mill will make processing even more efficient.

Wall to wall Sheetrock

The ubiquity of gypsum boards in construction is easy to acknowledge. Different thicknesses are created for different uses. In Sweetwater, USG was the first to manufacture half-inch, as well as tapered, Sheetrock panels.

Jeff Grimland, the regional director of manufacturing for USG, explained the properties of his company’s product.

“The neat thing about gypsum is if you grind it and cook it to 300 degrees, it becomes basically like plaster,” he said. “It's a chemical reaction, so now it's chemically in-demand for water.”

At that point, you can add water to it, fashioning it into any shape that you want. When it dries, it returns to a rock-like state in that new shape.”

Grimland held both his hands up, as if he were cupping two separate items.

“So, sheet – “ he said, waving one hand, “– rock,” he finished, clapping them together.

In a destructive fire, he added, those rocklike properties provide extra time for fire fighters to extinguish the flames, or for anyone inside the building to still escape, as those conditions cause the material to further solidify.

“As the heat and the flame are going against that wall, it creates an automatic barrier,” he explained. “So that's how you get a one-hour rated wall, a two-hour rated wall, depending on how you build that wall.

“That's what makes gypsum really cool.”

'A part of the family'

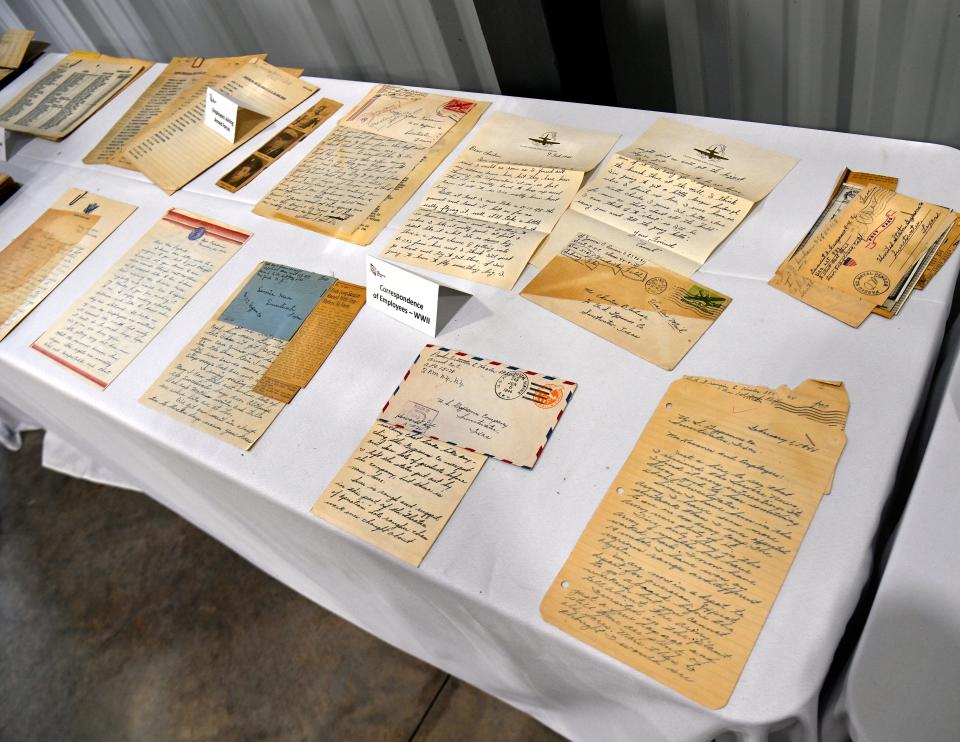

But it may not be the only thing really cool to come out of the plant, at least from the perspective of the correspondence on display Tuesday. USB had a table filled with letters from men who went off to World War II writing the company, expressing their thanks for news about Sweetwater and describing as much as they could their experiences far from home.

“I think that's neat, and it shows that relationship, that we're not just an employer, we're not just a job, we're a part of the family,” Sanchez said. “A lot of your life is spent at work and the people really care about this environment.”

One hundred years is a long time to work on a relationship and the one between USG and Sweetwater is reflected in the longevity of its workers, many of whom have spent their entire lives working for one company.

“We have great employees and they care about their work, but they really care about the community,” Sanchez said. “It's a great partnership and our employees love to do things in the community to help make it better, and the community loves to support us. It's just been a great relationship throughout the years.”

USG has been resilient enough to weather not only the Great Depression, but everything that’s happened since, including the coronavirus pandemic.

“We had a lot of protocols; screening, mask wearing, we were cleaning everything, every day,” Sanchez said. “It took a lot of effort and a lot of work, but the key was to keep people working, keep bringing those paychecks home and keep sending that Sheetrock out.”

Taking care of their own

At one time, the plant employed as many as 600 people in the 1950s. These days it’s closer to 250 and like other industries, USG hasn’t been immune to the shortage of potential employees experienced in the workforce.

“We've seen that. But we have had to get creative in how we advertise and how we bring people in,” Sanchez said. “We have one of the best benefits programs in the area and we're known for our safety (program).”

When Sweetwater’s housing crisis in the early 20th Century began to abate, USG offered the employees living in the Pyramid homes the option of purchasing the buildings at low cost and moving them to wherever they wished in town. According to Grimland, some of those homes are still standing in Sweetwater.

It’s stories like Pyramid that Sanchez pointed to as examples of how the company set the standard early on how they take care of their own.

“You can make a great living working here, lots of people call it ‘The Golden Ticket,’” he said. “Once you get in with USG, you’re set for life.”

This article originally appeared on Wichita Falls Times Record News: In Sweetwater, a century of the 'Golden Ticket' is celebrated at USG