Volkswagen Wants to Sell Three Million EVs a Year; Here's the Full Story on the Platform They'll Ride On

Volkswagen is moving wholeheartedly to adopt electric vehicles, with an ambitious and expansive plan to have electric versions of every vehicle in the Volkswagen Group lineup within less than 15 years. The plan is already underway, as Volkswagen outlined at the launch of its Electric for All marketing campaign in Germany this month. The EV push is part of VW's plan to atone for its diesel-emissions sins. The strategy VW outlines is to bring to market 150,000 electric (BEV) and plug-in-hybrid (PHEV) vehicles by 2020. By 2025, the Volkswagen Group is shooting to have some 50 BEVs in production, along with 30 PHEVs. The VW brand alone is planning to sell about one million BEVs that year.

By 2030, every vehicle in the entire VW Group-roughly 300 models-will have some sort of electrified version, Lamborghinis and Bugattis included!

The VW brand alone accounts for some six million of the group's 11 million annual sales, and the slightly downmarket SEAT and Škoda brands make up about 1.6 million sales, so it's clear that VW needs to produce electric cars for those three most affordable brands if the company is to meet its ambitious sales goals. The company has announced it intends to price its electric cars about the same as its diesel models-which is to say, they won't be much more expensive than gasoline-powered cars.

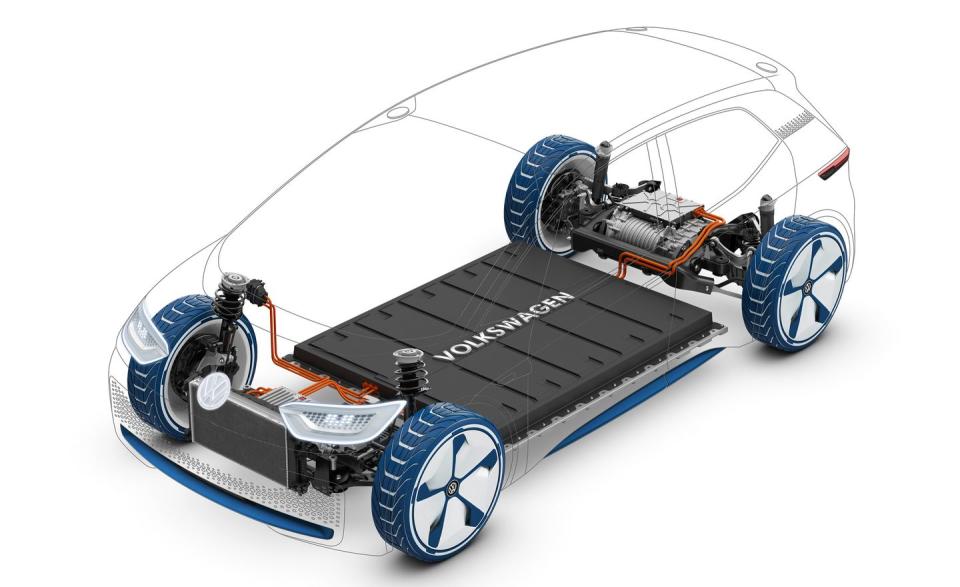

To help these electrics go mainstream, the company has developed an all-new platform designed exclusively for battery-powered electric vehicles. Its name is MEB, which stands for Modularer Electrobaukasten, or modular electrification tool kit. The MEB platform was designed solely for battery-powered vehicles. There is no provision for PHEV powertrains.

The first model to use the MEB platform will be the basic I.D., a Golf-size car, coming in 2020, along with the I.D. Crozz crossover. Both will be built in VW's Zwickau plant, which will receive a $1.4 billion transformation in 2019 to turn it into an all-electric plant by the end of 2020. Two years later, we'll see the Microbus-styled I.D. Buzz minivan and the I.D. Vizzion. By then, VW Group brands will have 27 MEB-based vehicles in production. Then, by 2025, there'll be a million I.D. products a year as production of models on the MEB platform shifts to several plants around the world.

The MEB platform places the battery in a flat, roughly eight-inch-thick slab beneath the floor of the passenger compartment. This position puts the car's heaviest component as low as possible to keep the center of gravity low and the central location distributes its weight evenly.

In fact, the MEB's weight distribution is so even that the electric-drive motor goes in the rear, making the MEB a rear-drive platform. Apparently, if the motor had been placed in front, the proportion of the weight on the front tires would have been too low to make front-wheel drive work effectively. However, there is a provision for mounting a second motor in front to achieve all-wheel drive.

The rear motor will likely have a base output of 168 horsepower, while a front motor might start in the 100-hp range. There will be more powerful versions offered, too, using the same motors and even the same power electronics. Power increases will come from software and gearing. By feeding more electricity to the motors and spinning them at higher rpm, VW will be able to achieve greater output from the same drive components, achieving economies of scale and keeping costs low.

Another advantage of the MEB platform is that it permits greater interior space than would be possible in a vehicle of similar length with an internal-combustion engine. That's because, since the motors are compact and the power electronics are small, MEB models will have longer wheelbases and shorter overhangs. To accommodate the many different vehicles it will underpin, the MEB wheelbase can be easily extended, and its width can be increased by extending the suspension arms.

The underfloor battery is a modular design that uses seven, eight, or 12 modules, each containing 24 rectangular lithium-ion cells. Pouch cells from LG Chem or prismatic cells from Samsung will fit the modules. Both cell types are rectangular, allowing the cells to be densely packed, but individual cell voltages and module temperatures are monitored, and a low-temperature cooling system maintains ideal battery temperatures. An additional high-temperature cooling circuit regulates the thermal behavior of the electric motor and power electronics.

The battery modules are housed in a stout, aluminum-framed housing that also serves as a structural member of the vehicle, adding appreciably to side crash resistance. The battery housing as a whole can also be removed from the bottom of the car for service.

VW didn't release the overall battery capacity, but a range of 50 to 80 kWh would be in the ballpark. According to VW, about 90 percent of that capacity is used to provide a range of 205 to 340 miles on the new, supposedly realistic, WLTP test procedure used in Europe, which translates to roughly 180 to 300 miles on the stricter EPA test cycle. Even the shortest-wheelbase MEB model can accommodate the largest battery pack, so it's expected that battery size choices will be one of the options available to buyers. There's also provision in the platform for the convenience of an inductive charging panel.

Interestingly, while the battery housing is made of aluminum, most of the MEB structure is steel, and there's no sign of carbon fiber or other exotic materials. This was a conscious decision designed to control the costs of the MEB-based cars. Moreover, the VW engineers make the case that weight is not so critical with BEVs-at least in city driving-because with regenerative braking, the system recovers most of the energy used to accelerate a car, regardless of its weight.

As to the basic running gear, the MEB uses a strut front suspension with a multi-link rear layout. The prototype platform on display used 215/55R-18 tires all around, but VW says that up to 21-inch-diameter wheels will be offered on some models. One unusual feature on this prototype was the use of rear drum brakes. This apparent anachronism is undoubtedly another cost saving for the less expensive MEB-based vehicle. It's hard to imagine that this feature will appear on any Audis.

In keeping with modern trends, the MEB vehicles will all be connected to the cloud. They are equipped with a new electronic architecture called e3, running a matching VW operating system, which includes three in-car application servers: ICAS1 runs the car, ICAS2 controls the displays and human interfaces, and ICAS3 is reserved for automated driving. This system will rely on a powerful central processor to replace many of today's individual car computers, and it will be monitored and upgradable online.

The human interface is expected to include a sophisticated augmented-reality projection on some models. Taking advantage of the MEB's excellent packaging efficiency, a one-cubic-foot space behind the dashboard is reserved for the hardware needed to operate this display.

Charging is relatively standard, with an onboard 11.0-kW charger, which works with a 220-volt wall box. In Europe, VW expects the wall box to be priced at less than $400, with six-to-nine-hour charging times. The platform is also designed to accept up to 125-kW DC fast charging, which will charge a depleted battery to 80 percent in about 30 minutes and are expected to be rolled out in the United States as well as in Europe.

Ready or not, VW is taking electric cars mainstream in the biggest possible way.

('You Might Also Like',)

Yahoo Autos

Yahoo Autos