Why the Hulett Unloader Is One of History's Greatest Forgotten Machines

George Hulett didn’t especially seem like the kind of person who could change the course of American history.

The native of Conneaut, Ohio—a Lake Erie town that’s as far northeast as you can get and still be in the Buckeye State—ended his formal schooling at age 18. He worked in groceries, owning a store not far from his hometown, before branching into manufacturing, which was driving the economy of nearby Cleveland, where he moved in 1881.

It seemed like an odd career change, but Hulett was an odd man. Author William D. Ellis, in his history of Cleveland’s infamous Cuyahoga River, described Hulett as a “bullfrog in a baggy suit” who wasn’t above putting a plug of tobacco in his mouth while taking meetings with captains of industry. In those appointments, “he talked as if he were still driving a team of draft horses back home on the farm.”

But Hulett had a farm boy’s ingenuity—and he was in the right place to capitalize on it. Though it’s tough to imagine now, Cleveland at the end of the 19th century was the Silicon Valley of its day, with more patent applications than anywhere else in the nation. The city was booming, thanks to John D. Rockefeller and oil refining, as well as shipping and the nascent steel industry.

Hulett watched the ships journey to Cleveland to docks on Lake Erie—or along the Cuyahoga River, the crooked river that proved so difficult to navigate that a spot fraught with shipwrecks is still known as the collision bend. At the time, cargo was unloaded one wheelbarrow at a time, by workers who were paid 10 cents a ton to unload the ship. It took a crew of 100 workers five days to unload 300 tons of cargo from a ship.

Time was money on the Great Lakes, which would freeze over in the winter, limiting the time it was navigable.

There had to be a better way.

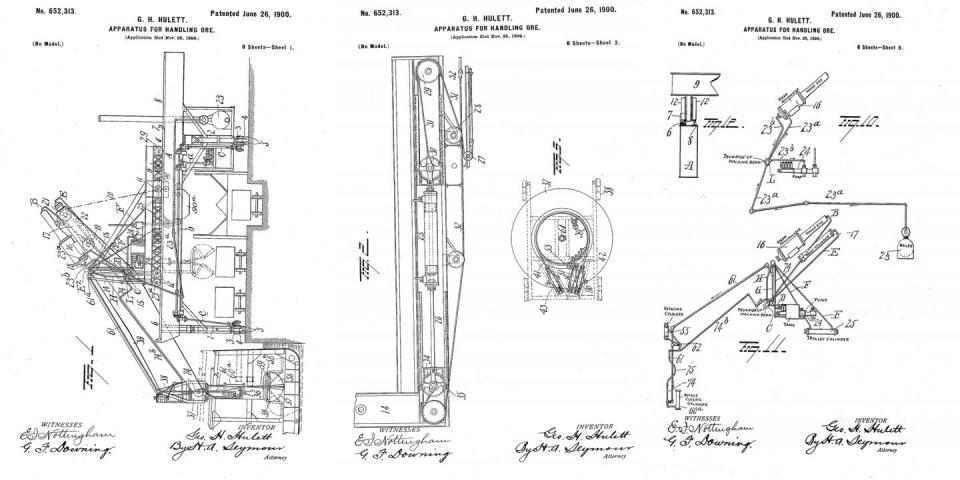

Patent No. 652,313A

Hulett, a 2006 inductee into the National Inventors Hall of Fame, received more than two dozen patents for various machines in his career. But his most important was Patent No. 652,313A in 1899, for a 92-foot-tall unloading apparatus that could scoop iron ore from a ship’s hold 10 tons at a time—an almost unfathomable number back then, even though more than 13 million tons of ore were shipped on the Great Lakes that year.

At first, the machine was merely theoretical. Hulett set a meeting with steel magnate Andrew Carnegie, who wanted to see it work before buying one. Hulett got a Cleveland-based company to take the leap of faith and build the unloader at a cost of $45,000—on spec.

The following year, Carnegie and his sidekick, Charles Schwab, went to Hulett’s hometown for a demonstration of a prototype. Neither man was the type to be easily impressed. Carnegie was a Scottish immigrant who’d risen from humble origins to one of the richest men in the world. While Schwab’s ascent wasn’t quite as meteoric, he’d gone from engineer to president of Carnegie’s company at the age of 35.

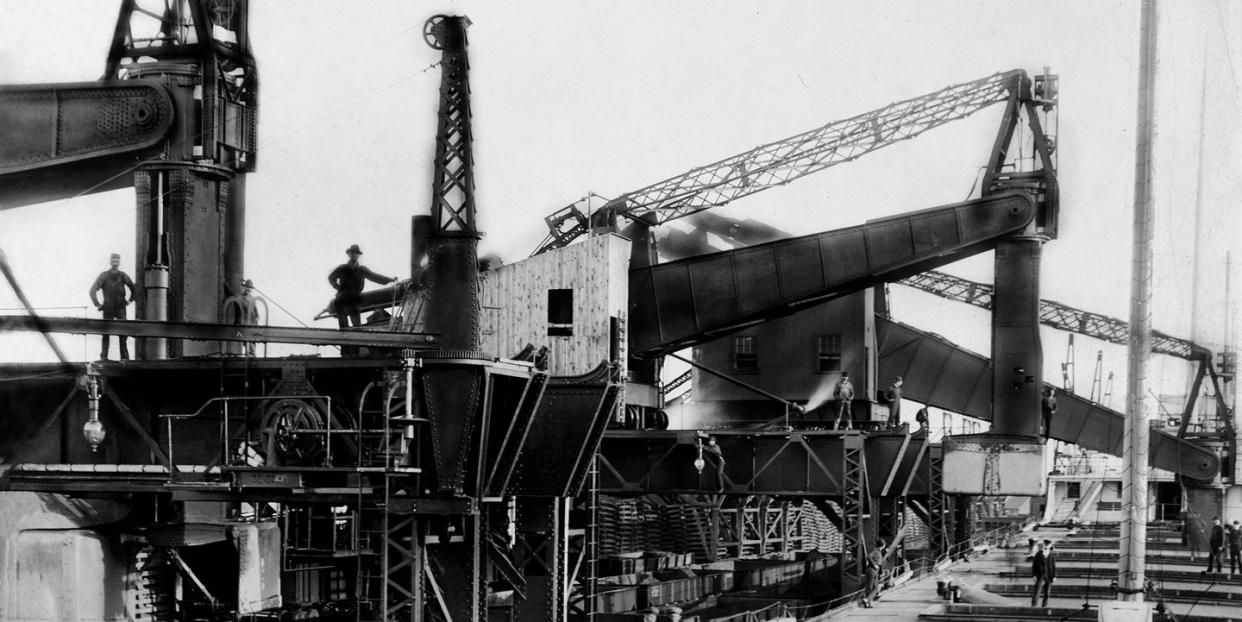

They saw the steam-powered machine, which was said to resemble a grasshopper arm, on a gantry built over railroad tracks. The machine lowered its arm—overbalanced by 6,000 pounds so gravity powered its descent—into the ship’s hold. The bucket at the end of the arm had a clamshell opening, gobbling up tons of iron ore and bringing it up to deposit into waiting train cars. The entire process to grab and dump one 10-ton scoop of ore took about a minute.

“In repose, this monster is the ugliest, ungainliest machine ever made,” Ellis wrote. “In action, it is sheer poetry.”

Carnegie had seen the future. He promptly bought the unloader—and four more. The machine, to be known as the Hulett unloader, or simply a Hulett, would soon revolutionize steelmaking.

“If we didn’t have the Huletts,” says Ray Saikus, past president of the Cleveland Chapter of the American Society of Mechanical Engineers (ASME), “we wouldn’t have been able to produce armaments that won World War I and II.”

By 1900, the Huletts were the kings of the Cuyahoga. And now they’re all gone.

Rewriting the Story of Steel

The effects of the Hulett were instantaneous and far-reaching.

“The methods of loading and unloading were a transformative part of the Great Lakes,” says Chris Gillcrist, director of the National Museum of the Great Lakes in Toledo. “And the Huletts had a lot to do with that.”

Ships could be unloaded with a crew of 25—a far cry from the hundreds previously required—and they worked the machine. One brave soul actually did the unloading, riding atop the arm that controlled its dip into the ship’s hold. What took a week could now be done in a day. Almost instantly, the cost of shipping iron ore decreased from 18 to six cents a ton.

The Huletts changed the very form of the ships that sailed the Great Lakes. Prior to their invention, the big Great Lakes transporters were so-called “whaleback” ships, designed by Great Lakes ship captain Alexander McDougall, another native of Scotland. As their name implies, the freighters had curved hulls and, when fully laden, resembled a whale sailing the Great Lakes. New ships were built to accommodate the Huletts with great big cargo holds unencumbered by deck beams. “The Huletts made whalebacks obsolete,” Gillcrist says, noting they’d virtually vanished from the Great Lakes by the 1930s.

Because they could be unloaded faster, ships could be made bigger. Great Lakes freighters grew by 100 feet in just the first decade after Hulett received his patent.

“The increase in size of lake ore carriers from 300 to 625 feet in length and from 3,000 to 13,000 tons in capacity in the past 30 years has been largely the result of improvements in unloading,” wrote R.C. Allen of Oglebay Norton in 1923, on the occasion of Hulett’s death.

Within a decade, Huletts could be found at every major port on Lake Erie. At their peak, there were 77 Huletts, almost all on the Great Lakes. There were a couple on the East Coast, but the Huletts, which couldn't be adjusted for ocean tides, were primarily tools for the Great Lakes.

Ultimately, electricity replaced steam power and buckets got bigger, with the capability to take 17 tons per scoop per minute. But the same basic technology remained.

“They never wear out and nobody’s ever designed or built a machine that will do the job better, faster, or more economically,” Robert Anslow, the man who sold the Huletts, told the Cleveland Plain Dealer in 1969.

The first part was definitely true. But the technology that would supplant the Huletts was nearly as old as they were. It just took a half a century to perfect it.

A Rapid Rise and Fall

In 1902—four years after Hulett received his patent and three after the unloader was first demonstrated in Conneaut—the Hennepin set out to sea, retrofitted as the first self-unloading ship. Launched as the George H. Dyer 14 years earlier, the 220-foot craft was already dwarfed by ships twice its size. It carved out a niche as a self-unloader for the next 25 years. Six years later after the Hennepin, the Wyandotte launched as the first ship built as a self-unloader.

The Huletts’ efficiency ultimately helped contribute to their undoing. As they reduced unloading and transportation costs, they also reduced the cost of steel production—which could then be used to make bigger ships. In 1927, the Carl D. Bradley became the first self-unloader to take the Queen of the Lakes title as the Great Lakes’ longest ship, at 639 feet.

Self-unloading ships have followed the same basic principle since their inception, with the ship’s hold funneling to a conveyor under it, which carries the ship’s cargo to another conveyor that brings it up on deck, where it can be delivered through another conveyor into nearby vehicles. Back then, it could work for soft coal and other material, but it wasn’t able to successfully transport heavier cargo, like iron ore.

But in the 1950s, engineers developed a process to form the iron ore into small concentrated pellets, which were easier to ship and unload with self-unloaders. The Huletts’ days were numbered.

“The mining industry itself had changed,” Gillcrist says. “Once that happened, all the boats started going toward self-unloaders, which made the Huletts obsolete. Now, you could unload cargo anywhere, and you didn’t need a special crew to do it, which helped reduce expenses.”

The steel industry also faced tectonic shifts. The Great Lakes cities that were home to tremendous steel production—as well as cities like Pittsburgh and Youngstown, which weren’t on the Great Lakes, but were close enough to take advantage of their shipping capacity—saw mills close and companies fold. The Midwestern cities that were destinations for the train cars the Huletts loaded with ore no longer needed them.

And so the Huletts, which had lifted more than 100 million tons of ore in roughly a century, were no longer needed.

All That Remains

Huletts could be found throughout the lower Great Lakes, from Chicago to Buffalo. But if there’s one city that’s most closely associated with the giant unloaders, it’s Cleveland. The unloader’s inventor and namesake spent most of his adult life there. Many of the unloaders were built by Wellman-Seaver Morgan in Cleveland. And boasting 14 unloaders at its peak, no city had more, making it the largest ore shipping center in the U.S.

For generations, four of the massive unloaders stood like sentinels watching the Cleveland coastline as part of the Pennsylvania Railroad docks on Whiskey Island. In fact, if you’ve ever seen a Hulett, it was probably those four, which can be seen in the opening credits of Major League.

After the Pennsylvania Railroad’s merger with the New York Central to form Penn Central (and that company’s subsequent bankruptcy), the unloaders passed to Conrail, which had no need for them. By 1987, they were only unloading around 30 ships a year—just 10 percent of what they’d done previously—and the Huletts were finally decommissioned in 1992, the last of their kind on Lake Erie. (Two more on the Calumet River in Chicago lasted until 1999.)

Conrail sought a permit to demolish the Huletts, but a historic preservation movement rose up in response. In 1998, ASME declared the Huletts a Historic Mechanical Engineering Landmark, one of just 275 sites in the world to reserve such a designation. The Huletts are also listed on the National Register of Historic Places.

Ultimately, two of the four Cleveland Huletts were torn down for scrap, while the other two were disassembled and remain in pieces on Whiskey Island, which has become a popular recreation destination in Cleveland. The city remains a major port, with 13 million tons of cargo annually. But in a state where tourism is a multibillion-dollar industry, people are starting to see the value of the lakefront for recreation. Barges now share space on the Cuyahoga with high school crew teams. People now live in the Flats, with a variety of restaurants and bars on the waterfront.

And that leads to the question of what to do with the remnants of the Huletts on Whiskey Island. Saikus says getting them rebuilt wouldn’t be the problem, even with an estimated cost of $10 million. “A lot of our members are corporate heads,” he says. “Money isn’t the issue.”

Rather, he says, it’s getting local governmental entities on board. It’s been a struggle for the last 20 years, but an answer could be at hand. The Cleveland Landmarks Commission approved using part of the Hulett for a display at North Coast Harbor, at the end of East Ninth Street in downtown Cleveland.

Using just a part, Saikus says, would be a betrayal of history. But it’s better than nothing.

“The Huletts were Cleveland’s unique contribution to American prosperity,” he says. “We have to take pride in that.”

You Might Also Like